One of those ridiculously simple solutions that gave me enough of a headache that I thought it was worth posting.

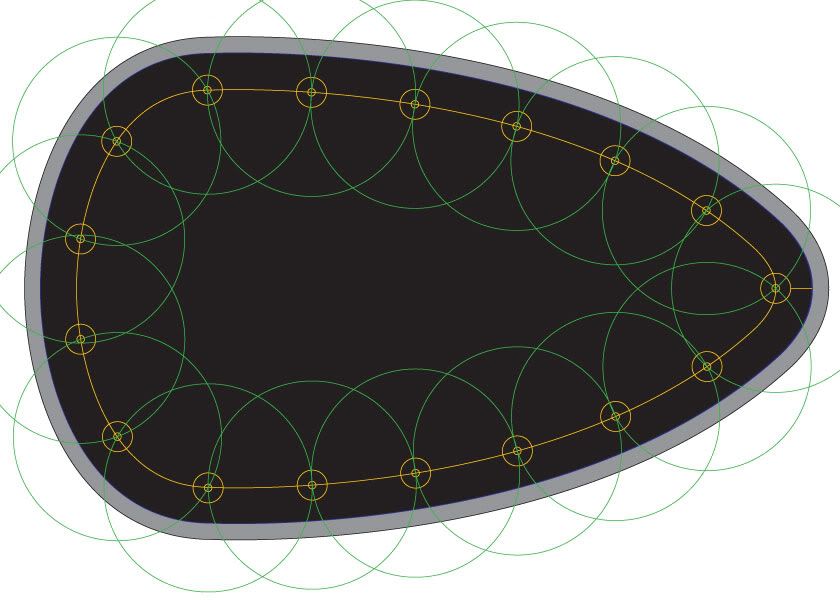

1: draw up a seat pan-gray (this one ended up being modified from whats pictured)

2: figure out where the leather is going-black

3: figure out how far from the edge your rivets will be, and where the centers are, draw a line that will pass through the centers of all the rivets will be(yellow line)

4: measure the circumference of your your rivet spacing line(use flexible ruler or string)

5: figure out approximately how far apart you want the rivets to be, based on thickness of material, rivet size, and visual effect (the leather we use is over 1/4" thick, and the rivets are something like 1/2" copper). Divide the circumference by this spacing to figure out how many rivets you will have, and adjust the spacing until it divides fairly evenly.

6: using circles with the same radius as your rivet spacing, start with center right point, use the intersection of the circles with the rivet line to figure out where your rivets will go. -green

7: curse as you make small adjustments and redo the circles 2-3 times in order to get spacing perfect. make sure the rivet placement works with the bend in the seat.

notes:

-Mocking it up on the computer makes it a bit easier to play with small circle adjustments, but the set up is exactly the same for using a compass and doing it by hand.

-note that this is visually even rivet spacing, which means that the straight line between each rivet is the same. For true even spacing on a curve, use a flexible curve ruler and do it by hand, if you have lots of rivets/tight curves, this may or may not look better.

-your life will be 10 times easier if you drill the holes before you bend the seat pan.

Result shown below, we had it water jet with pilot holes for accuracy, and well frankly because drilling the holes is a pain in the ass and when doing it by hand one of them always seems to be out of line with the rest.

Comment