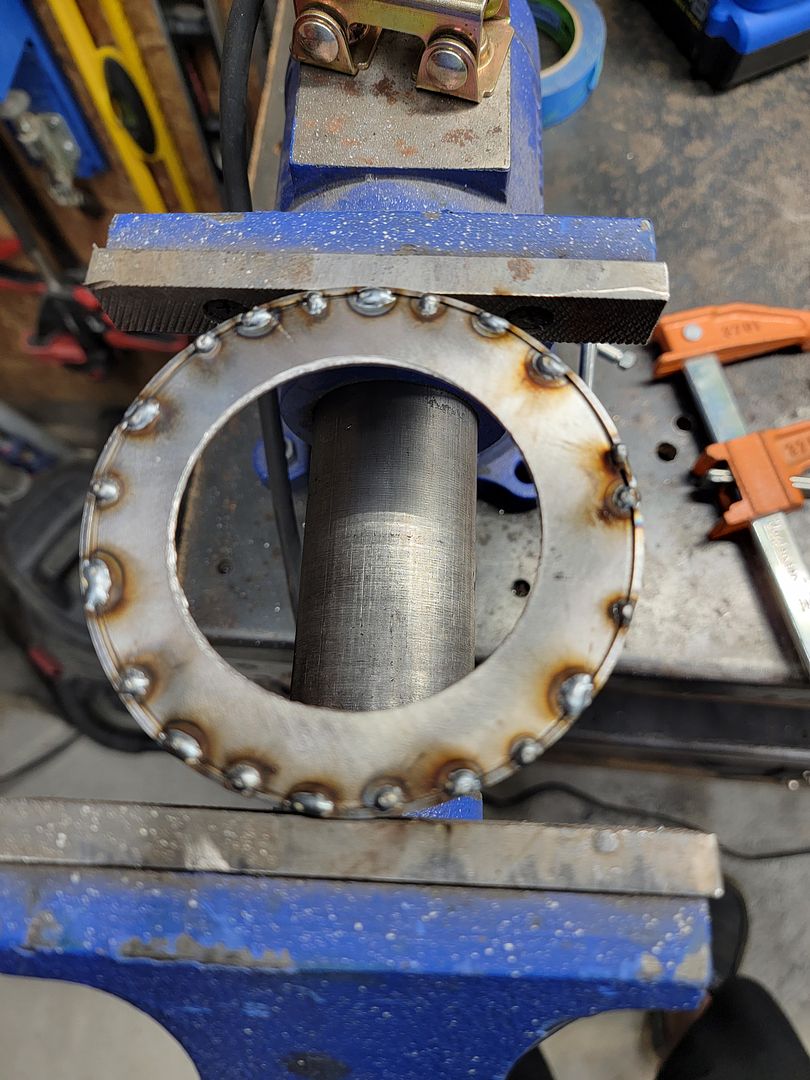

lol thanks dude, I have a lot of hours to put in before my welds start looking nice but I can at least get some shit to stick together!

The Killers Resurrection

Collapse

Desktop Ad Forum Top

Collapse

Mobile ad top forum

Collapse

X

-

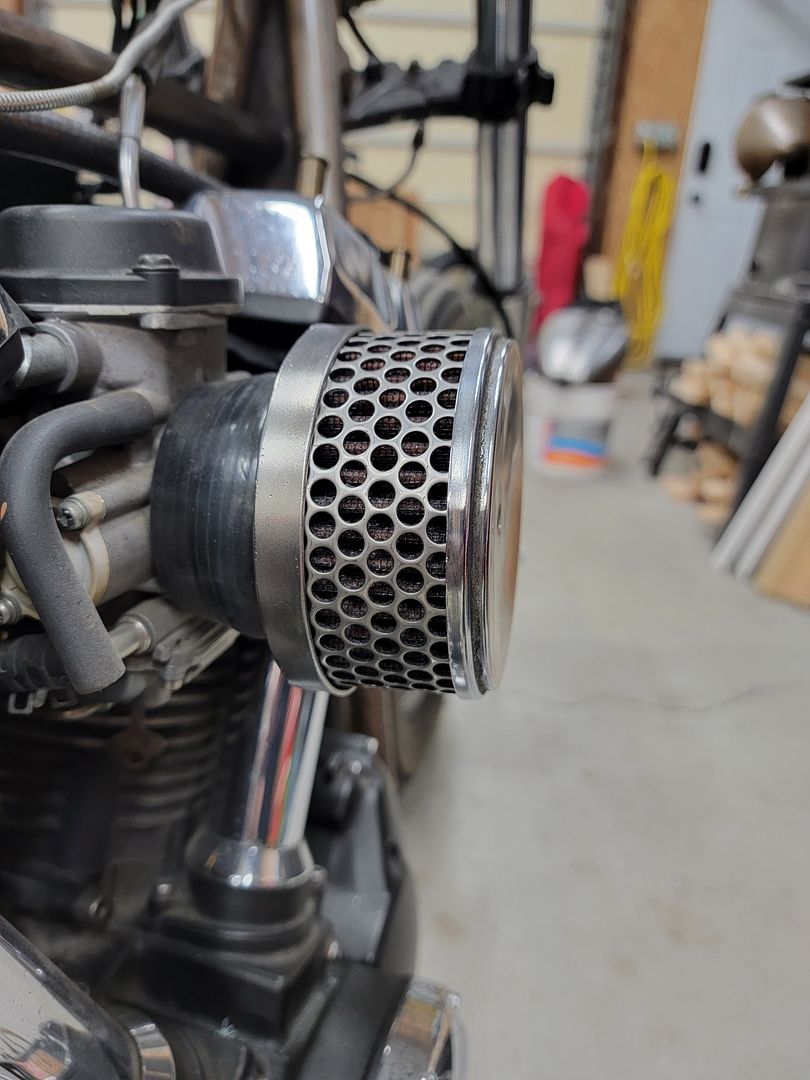

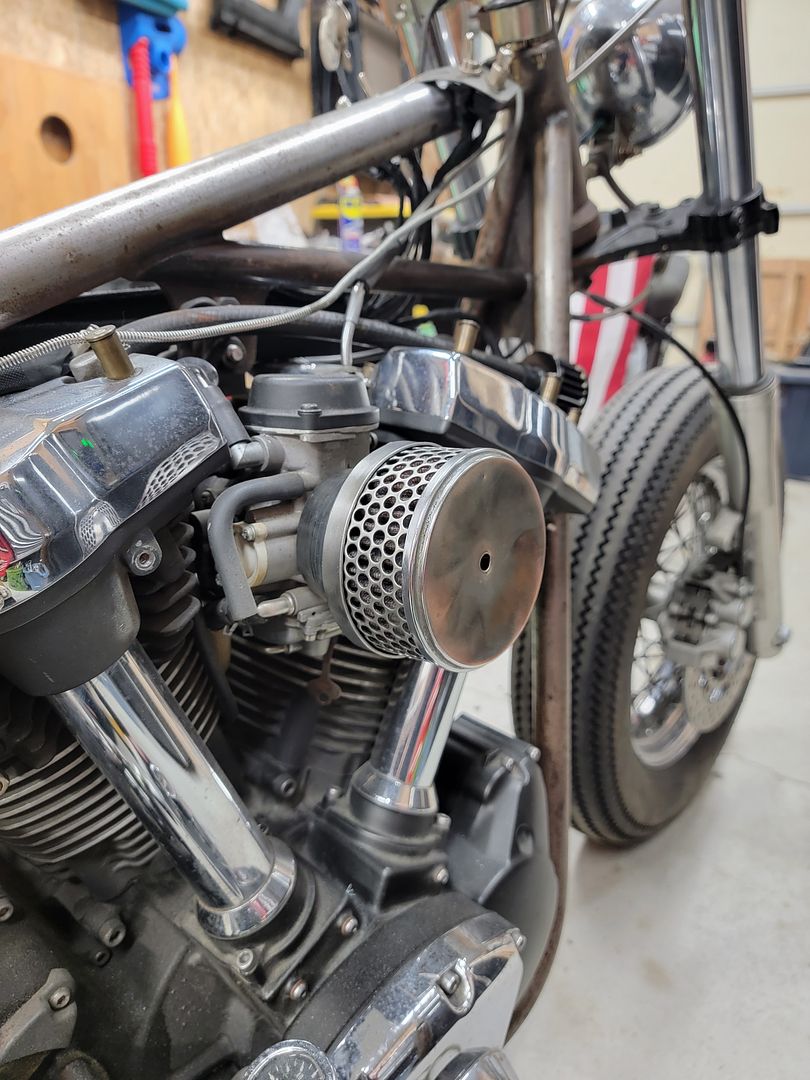

Well I have the wiring 95% of the way.* Waiting on a few small things before I can say its complete. I really hope the turn signal relay and possibly resistor fix my not blinking turn signal issue. I at least got it mostly wrapped back up and looking decent.* What a pain this has been but man everything is nice and tidy now.* All of the bulky items are packed into the saddle bag.

Comment

-

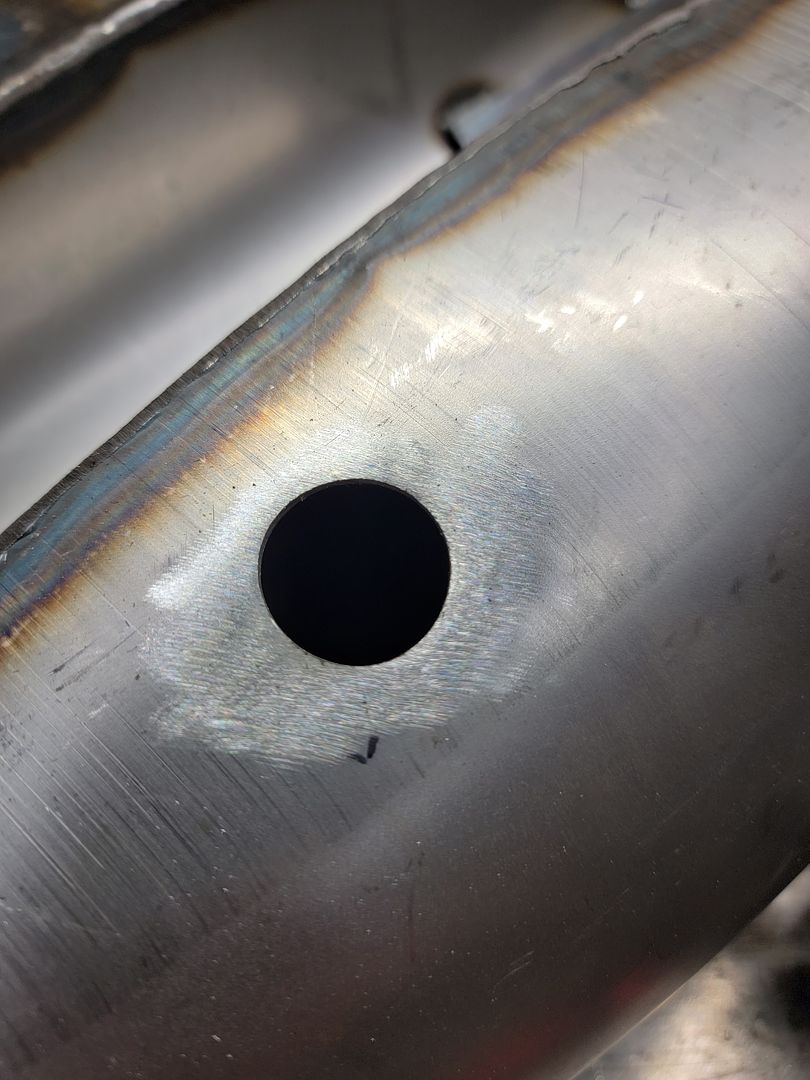

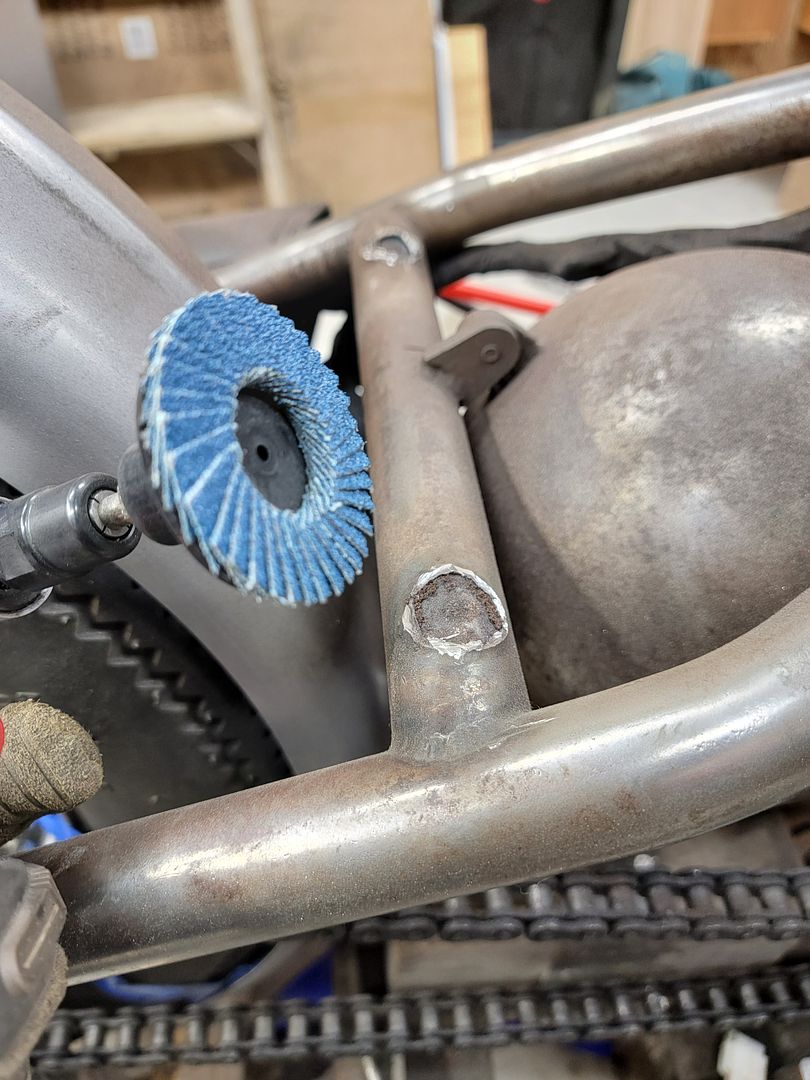

So I chanced my skills of welding on the tank tonight and I think it looks okay (At least its underneath the tank lol)* Now I just have to get some plugs and test for leaks.

Starting to think more about the fender and seat placement.* I plan on making a sissy bar so I will have bungs welded to the rear of the fender that the sissy bar will mount to.* I think the front portion of the fender where I will tie into the upper and lower part of the frame tubes will just end up being flat plates welded to the fender and frame with one being drilled and tapped and the other being slotted so I have some small adjustment on the fender placement.

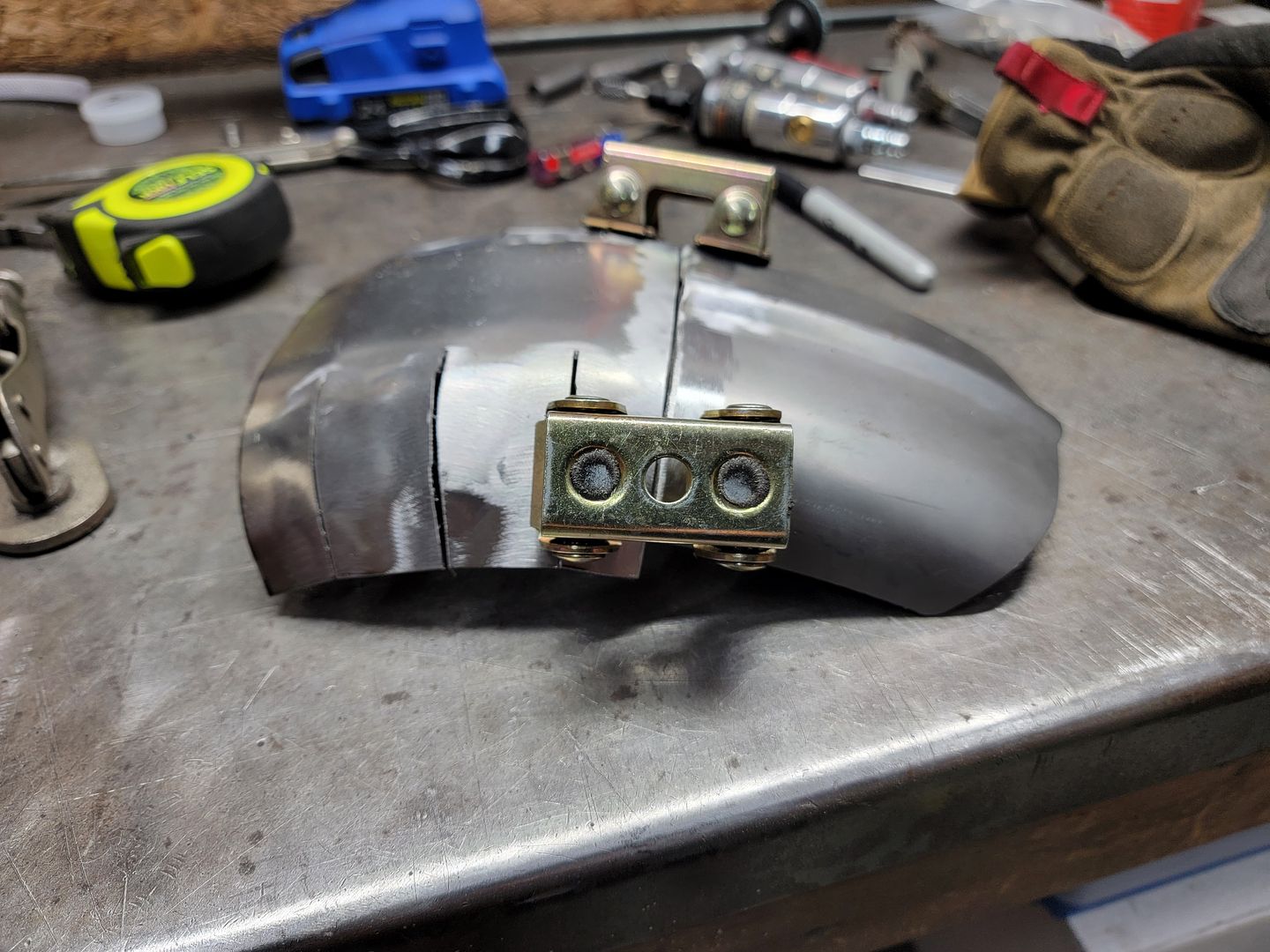

The seat I am going for will be a rigid style seat that has to sit flush to the top of the wish bone portion of the frame.* This means I have to remove my old seat bungs and probably grind the oil tank mounts down a touch to achieve this. I plan on mounting the front of the seat to a hinge bracket and somehow bolting the rear down to the frame or maybe even the fender.* Not 100% sure yet.

Comment

-

Unfortunately gasoline is much thinner than water. About 12 pounds per square inch of air and check with soap suds is way better than water. but nothing is totally proof against gasolines ability to wick through a tiny flus seam or an even smaller cold lap.

DustyDriving that train, high on cocaine

Casey Jones you better, watch your speed

Trouble ahead, trouble behind

And you know that notion just crossed my mindComment

-

Well I was fairly un lucky tonight.

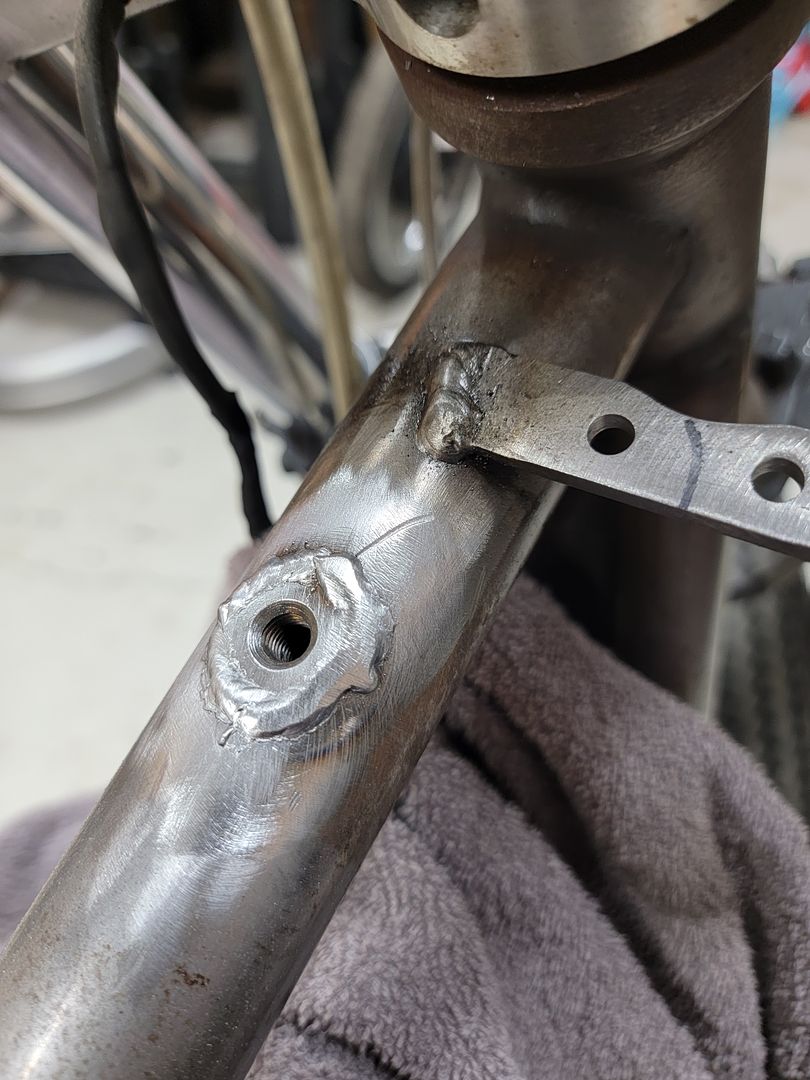

My plan was to get the (2) tank mount bungs welded into the frame and weld up the oil tank bracket to the frame as well.

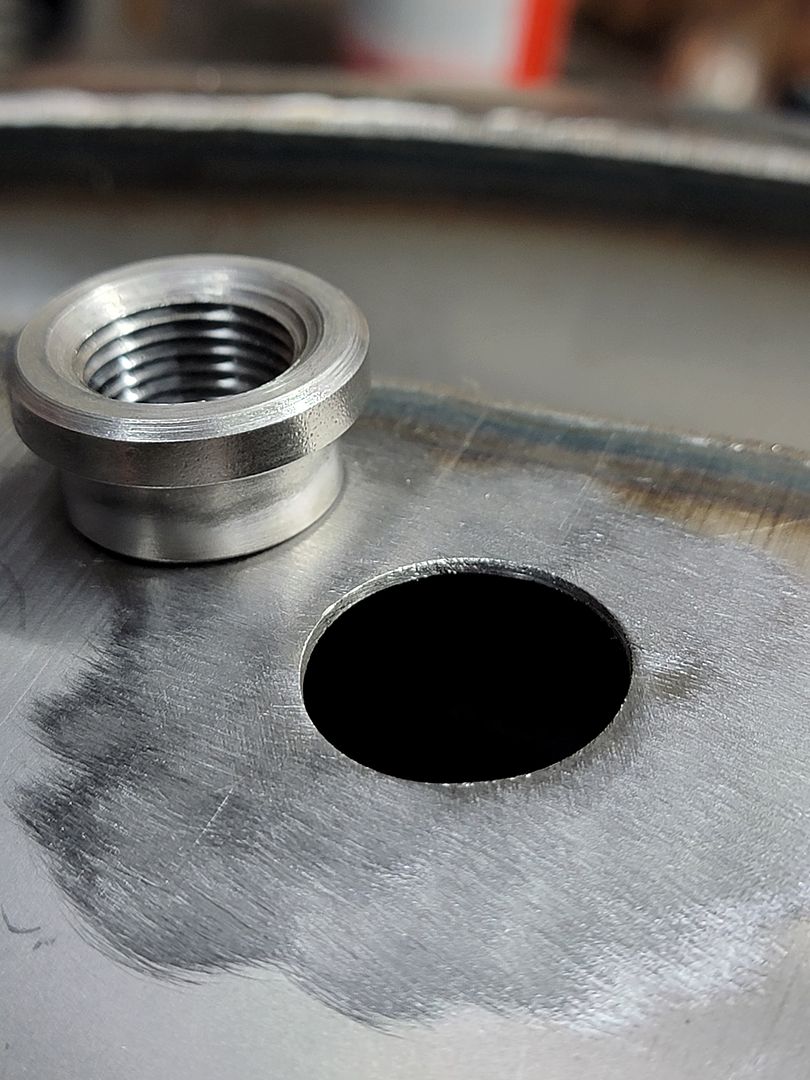

I drilled and ground the hole for the first lower bung and wouldn't you know it I dropped the bung in the hole (Bung hole) took me 45 minutes to fish it out from the bottom of the center tube with a magnet.

I then got it welded in and looking good. Started the upper bung which is right where the thread rod is now. Because of the weld around the original rod i broke a drill bit and my step bit nor me die grinder bit will touch it. (Carbide bits come tomorrow)

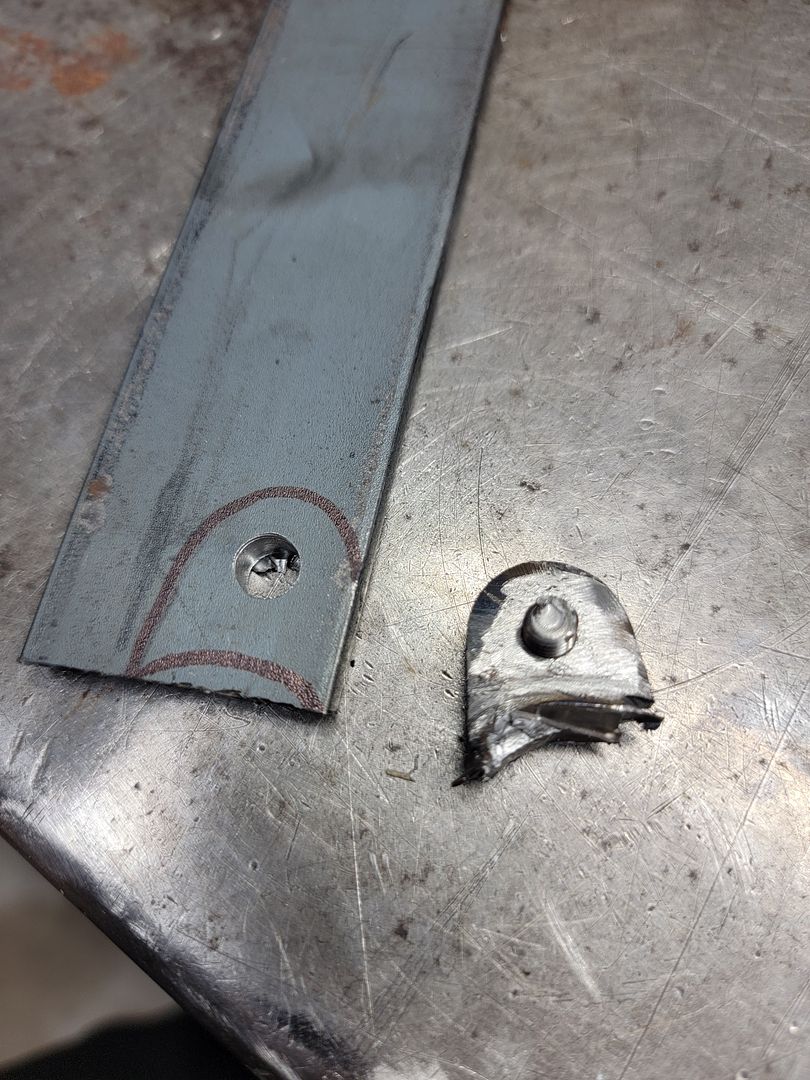

Lastly I welded up the oil tank bracket/tab. Everything was fine and then my stainless bolt gulled up when putting it back in. Sure enough i broke the bolt off in the tab. Cut the damn thing off and will have to make another.

1 Step forward 2 steps back ! Hopefully tomorrow will go better.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

Comment

-

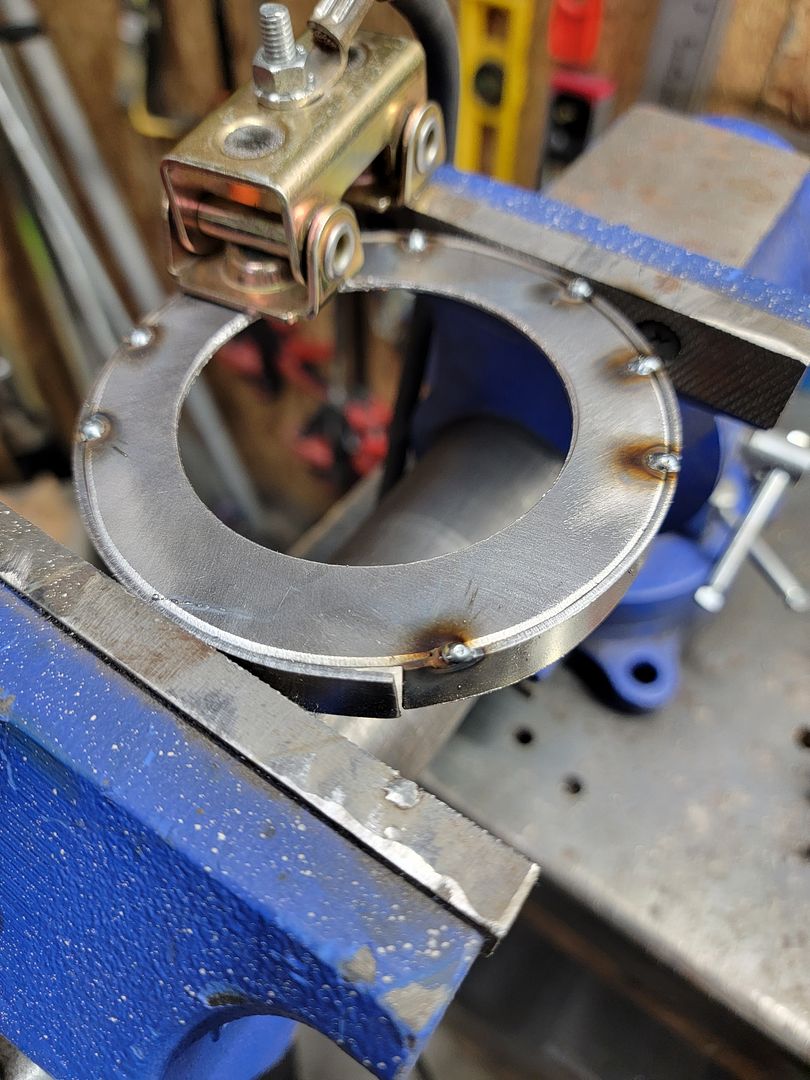

Made a new oil tank mounting tab. Went with a through hole this time vs a tapped hole. Was able to get that welded on halfway decent.

My carbide bits came in for my die grinder so I went to town on the upper tank mount bung and got the tank properly fitted to the bike.

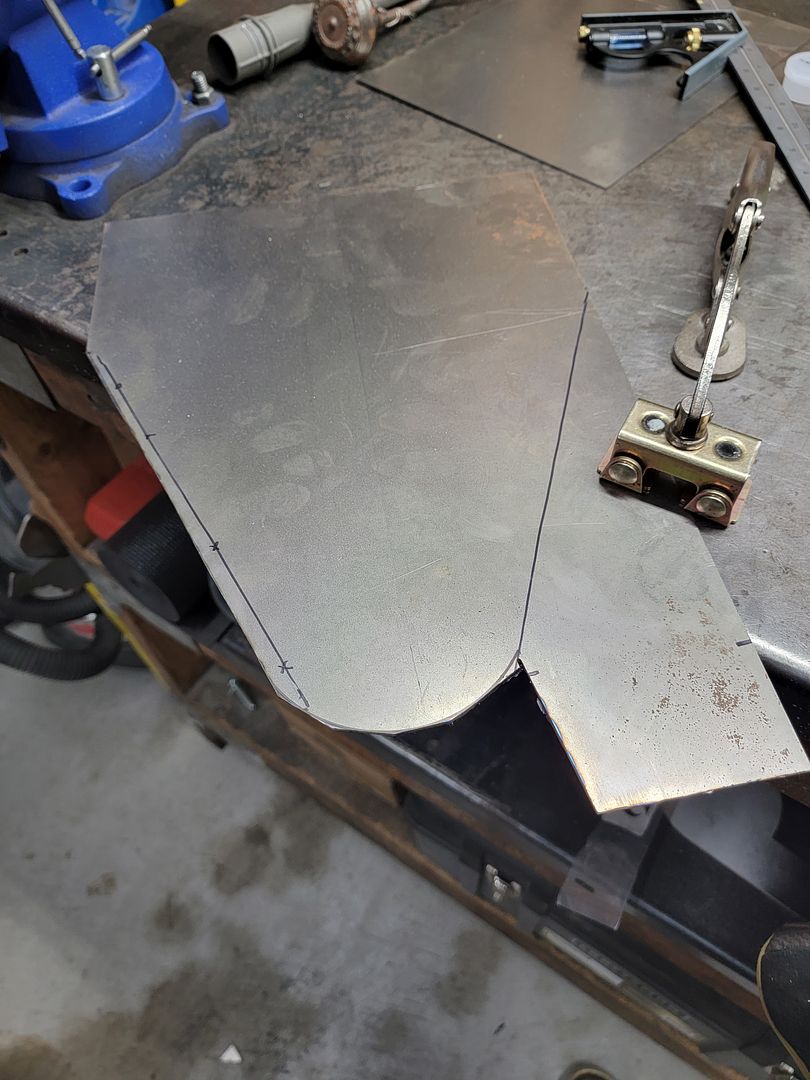

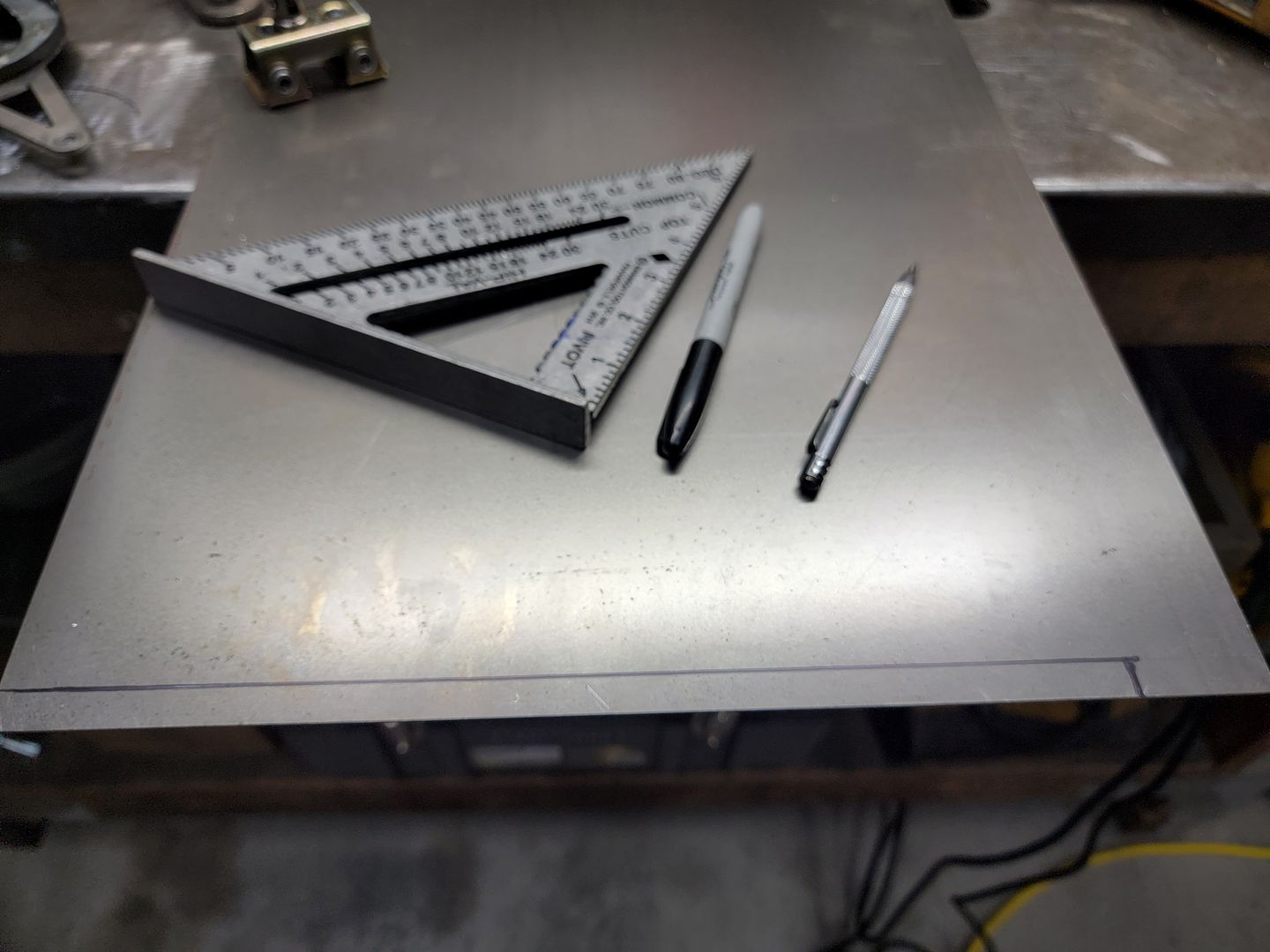

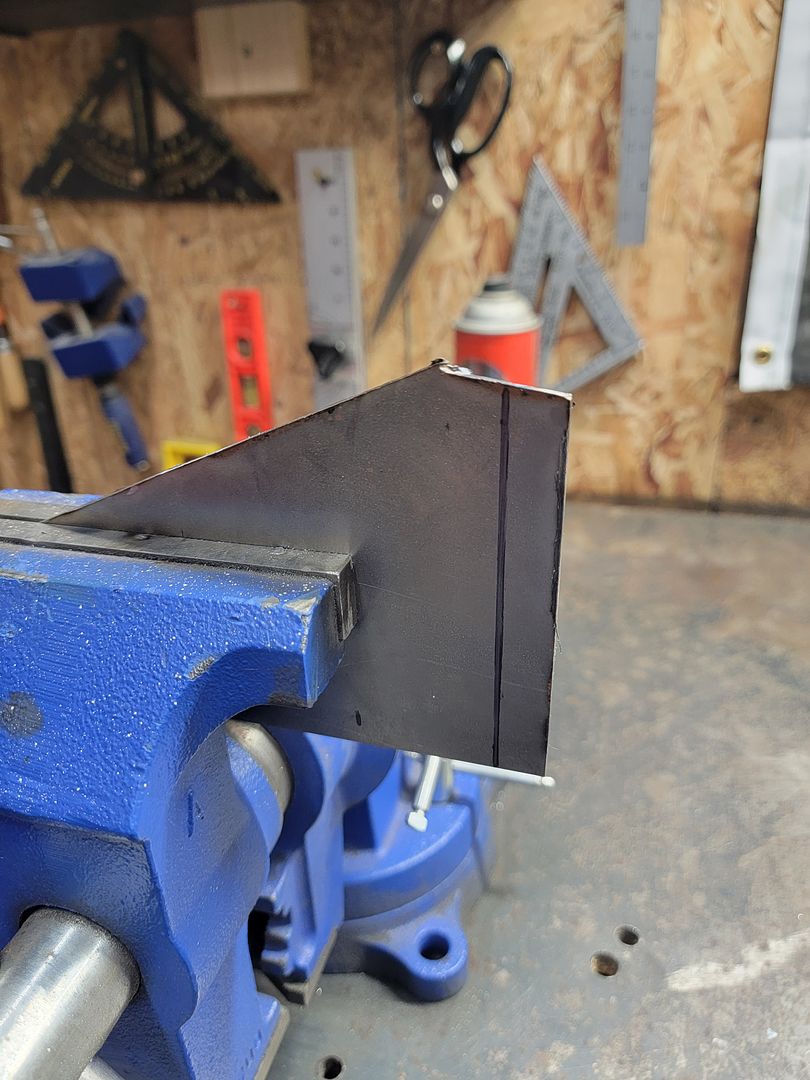

Cut a seat pan and started to brainstorm some ideas on mounting and how the back support area will look.

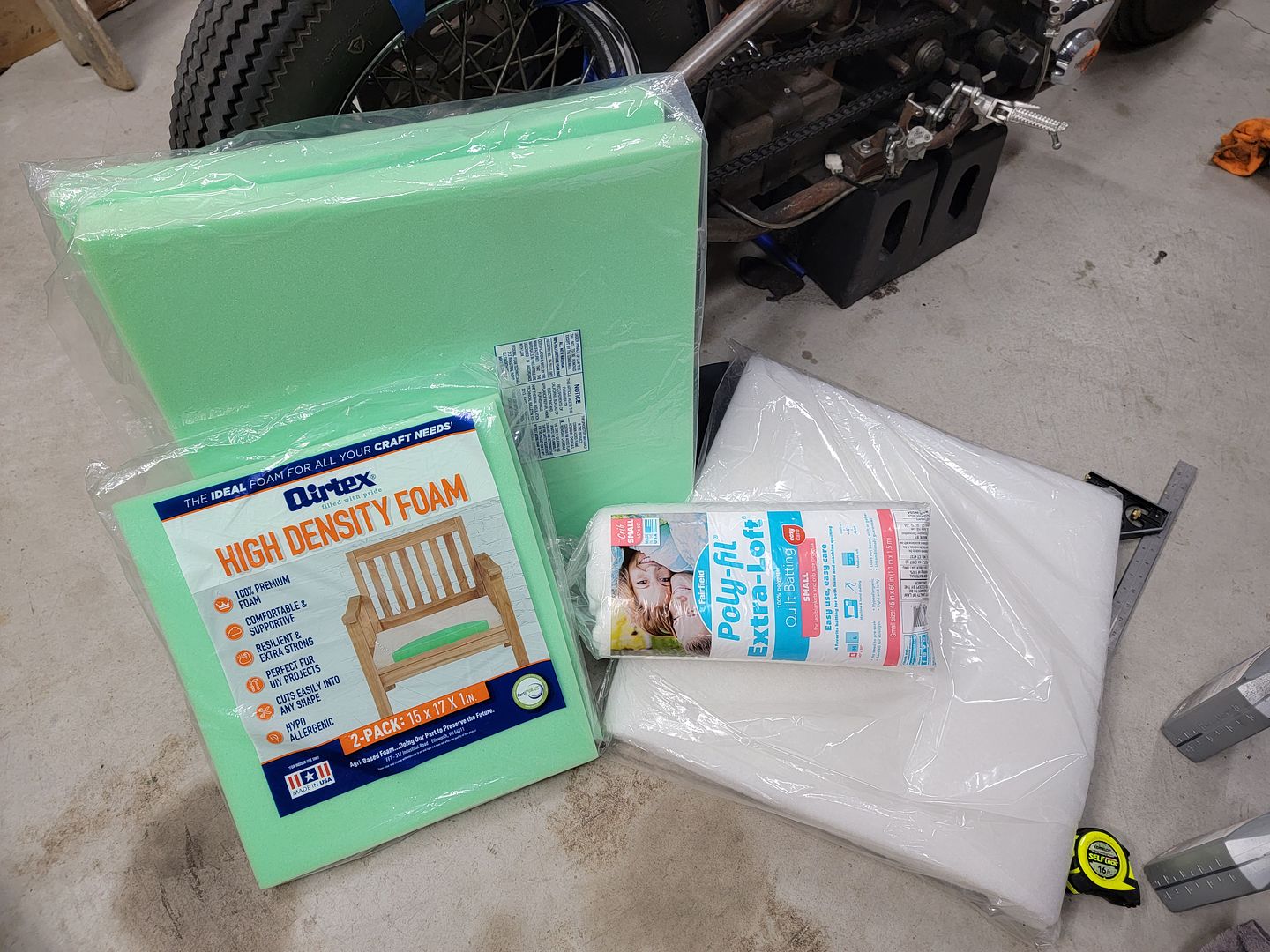

Did a quick sit test and I think 4 or 5 inches of foam is what feels the best on the cheeks. After the seat is wrapped and compressed I am hoping it will be roughly 2" tall.

Might bounce back and forth between the fender and seat until I have it all figured out.

Last edited by bnag0; 05-27-2022, 10:37 PM.

Last edited by bnag0; 05-27-2022, 10:37 PM.Comment

-

No sign of gas leakage from the tank, been about 12 hours now.

Got some special heat wrap in for the harness. Shouldn't notice it too much once the tank is in place.

Started into the seat pan. Still figuring shit out as I go... this might be the first of many pans before i get it right lol.

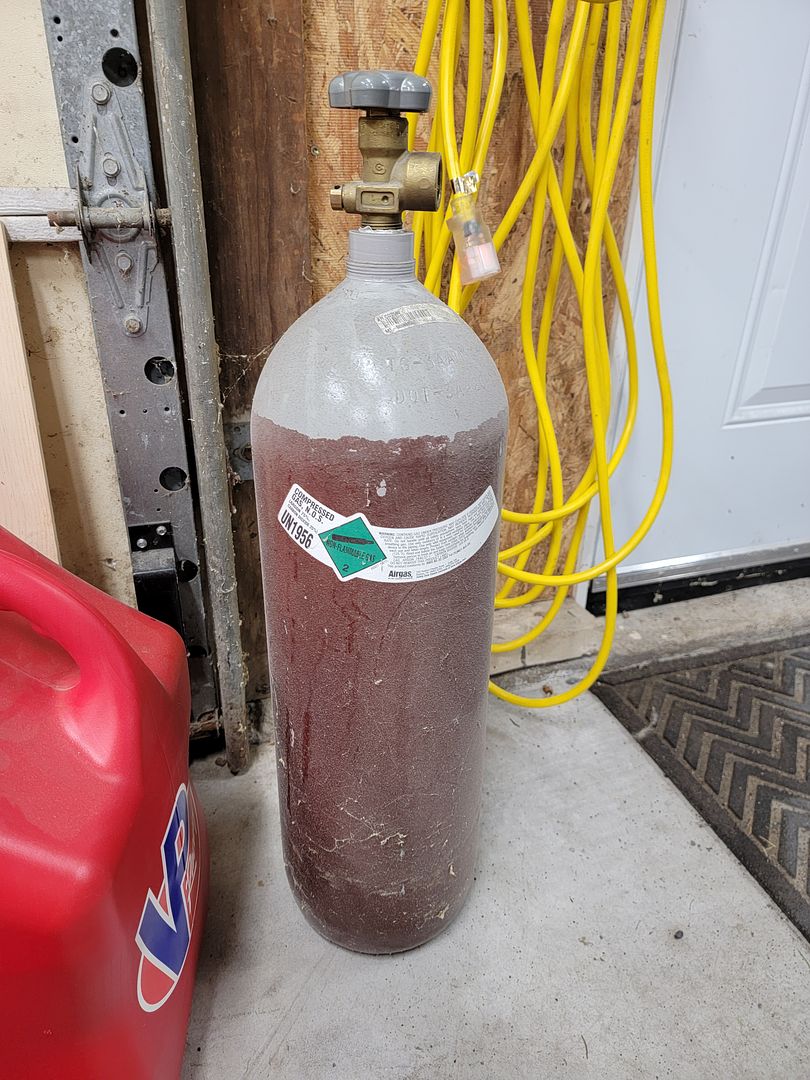

Of course I ran my bottle empty tonight... I will blame my poor welds on that this time around lol.

Will most likely hit up Walmart for a yoga mat or kneeling pads as it seams like that would be easier than the foam I purchased.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

[IMG]https://hosting.photobucket.com/images/dd425/brentnaegele/20220528_234441.jpg?

width=1920&height=1080&fit=bounds[/IMG]

Comment

-

I am hoping so Doom lol. I have only made solo seat pans in the past and left them un covered so this is definitly a bit of a challenge for me. I am attempting to make something similar to the le pera signature 2 or the drag specialties scorpion.

https://www.lowbrowcustoms.com/colle...rpion-seat-pad..

Time to upgrade your stock seat. LePera's Signature II Two Piece 2-Up Seat is designed to fit Rigid Frame motorcycles. Two-piece seat offers classic styling Narrower Pillion Area Molded one-piece foam foundation covered with premium grade black vinyl on a 16-gauge powder coated steel base plate Seat bottom carpeted to protect the fender Includes a universal nose bracket and hardware Made in the U.S.A.

Time to upgrade your stock seat. LePera's Signature II Two Piece 2-Up Seat is designed to fit Rigid Frame motorcycles. Two-piece seat offers classic styling Narrower Pillion Area Molded one-piece foam foundation covered with premium grade black vinyl on a 16-gauge powder coated steel base plate Seat bottom carpeted to protect the fender Includes a universal nose bracket and hardware Made in the U.S.A.Comment

-

Comment

-

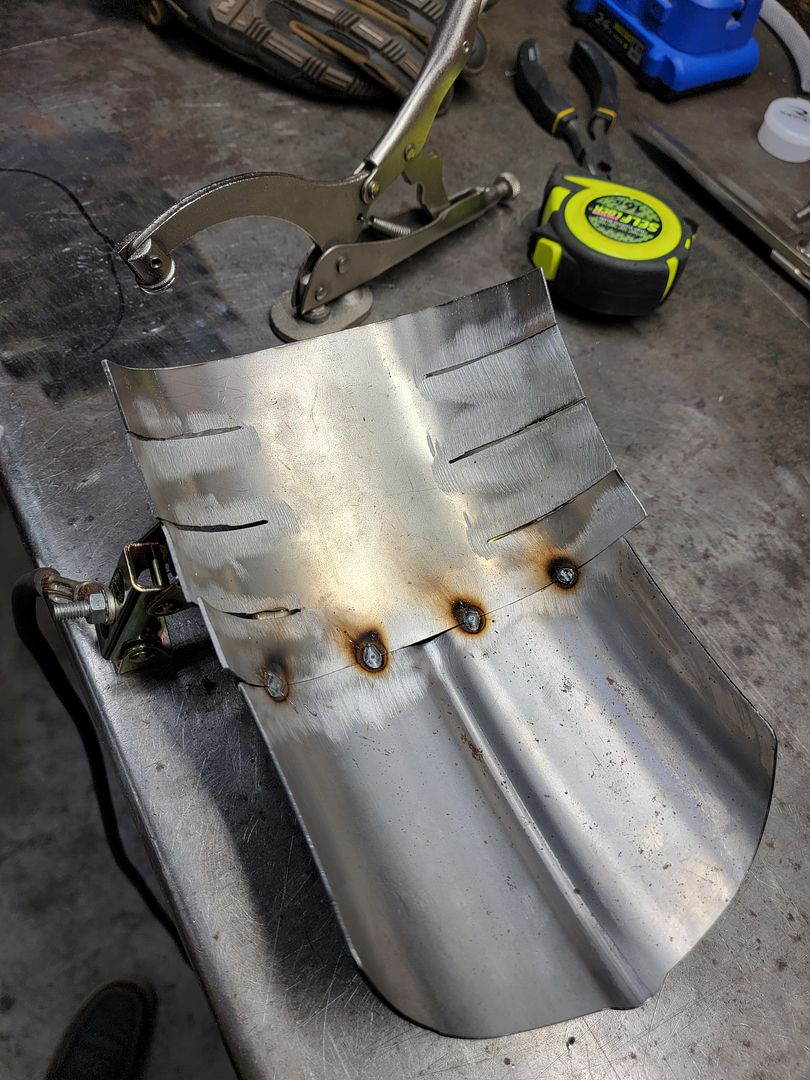

Added some rear gussets to the seat pan. Will be drilling (4) holes and welding in bolts that will pass through to the bottom. The (2) in the rear will pass through some brackets I weld onto the frame. The front (2) will bolt to a piece of flat bar that will then bolt to the frame. The idea is to give my seat a little bit of adjustment front to rear. Hoping I can start speeding up the process so I can ride this damn thing this season.

Comment

300 mobile ad bottom forum

Collapse

Comment