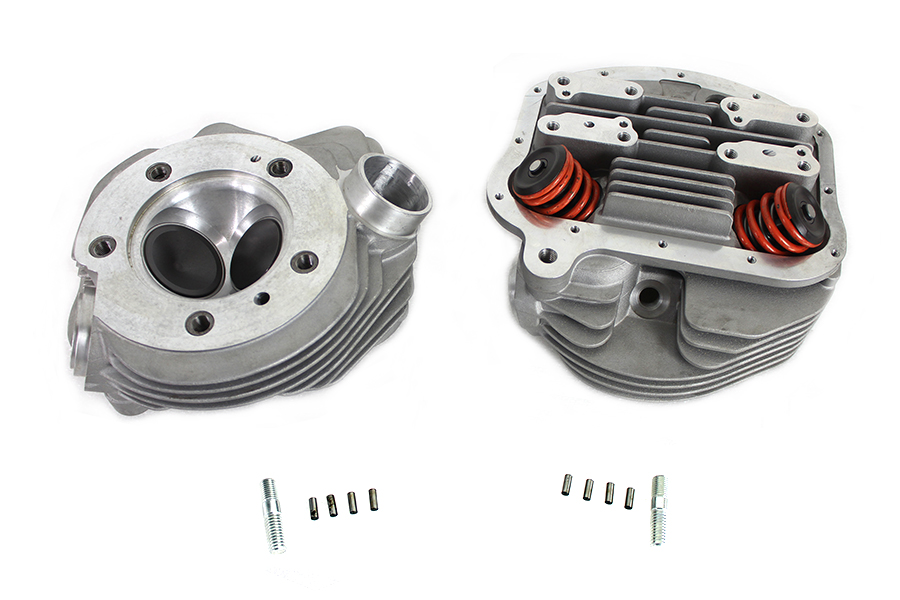

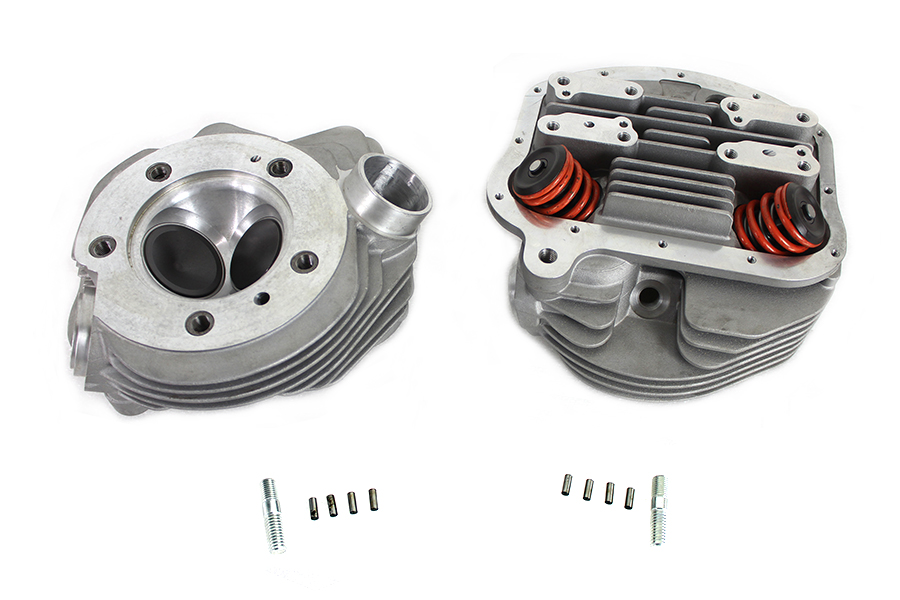

Hmm. How good are the stock repro heads?

They are very nice indeed ... Got hard seats and sporting Shovel intakes valves ..

Also they have the Shovel combustion chamber and 3/4" reach plugs ..

It would be interesting to retain a plumber intake for looks if it will seal reliably

Matter of personal choice there .. But if it was me, I'd go with the 55-up O-rings cause of they are easier to work with and no alum. threads that can give up the ghost ..

(I'd use quality Rectorseal dope or perhaps Hylomar unless there's another anti-seize/sealant that kicks more ass.) I've removed and installed a few plumber intakes long ago on customer bikes with no comebacks but haven't any long term personal experience riding a scoot with them. The customer Pans I worked on were just beat old choppers and nothing special so I never got to get deep into studying them. This will be educational fun.

I don't want to replace the jugs I just bought in dat stroker kit with Shovel jugs and prefer to keep it all Pan/PseudoPan.

Yeah, I hear that ... ^^

I've a few good Super B's with pump kits and am used to those, but how much would I be giving up HP wise ??

A bunch of ponies would be running on three legs if you used a Linkert carb ...

Ya just gained 26 more hungry cubes than what was there, that Super-B with a pumper is the perfect carb for the state of build your motor is headed ..

If needed, I got a S&S Pan manifold that is used ...

Can throw it in your pile of parts, if ya want it ??

... OR ...

Buy a new Panifold from Jason Phares ..

(and where in the powerband) running the M74 (or another and if so, which?) Linkert with that stroker kit? I've rebuilt a couple that didn't need much attention but never tuned one.

My interest is low end grunt and highway roll-ons, not high RPMs. What cam would best suit a two-wheeled tractor? It will be a solo bike and I like tall final drive gearing but I don't lug engines.

Later in the day I'll run a few Acc. Programs with diff. cam grinds, I'm more than sure we can pick a grind that will suit your needs ..

Box will be a late five speed in a Softail case (for the electric start, I can kick just fine but old age is ruthless and my ass might fall off without warning). Please put that Softail trans posted above in the Farmall pile. At that price there's no point in me hunting a Delkron case and buying the little shit to use my good splined shaft takeout. Like a sore dick, I can't beat it. The door chrome will be solved with kicker kit.

Can throw it in your pile of parts ... ??

Kinda thought you'd like that deal ... It's now belongs to you ...

Ya do know that 5th gear will need to be changed out from belt spline to a chain spline .... Be mighty hard to run a belt for final drive ...

And on the motor sprocket shaft if we run the 55-64 shaft it will be bout 3/8 of a inch short to line up with the 5-speed trans ...

We can get a 70-up special shaft that fits our needs ... That way there will be no need for attaining a special motor pully ..

As for threads maybe it would be better to tack my adventures onto this one for a Pan drivetrain MegaThread comparing options since the builds are similar.

They are very nice indeed ... Got hard seats and sporting Shovel intakes valves ..

Also they have the Shovel combustion chamber and 3/4" reach plugs ..

It would be interesting to retain a plumber intake for looks if it will seal reliably

Matter of personal choice there .. But if it was me, I'd go with the 55-up O-rings cause of they are easier to work with and no alum. threads that can give up the ghost ..

(I'd use quality Rectorseal dope or perhaps Hylomar unless there's another anti-seize/sealant that kicks more ass.) I've removed and installed a few plumber intakes long ago on customer bikes with no comebacks but haven't any long term personal experience riding a scoot with them. The customer Pans I worked on were just beat old choppers and nothing special so I never got to get deep into studying them. This will be educational fun.

I don't want to replace the jugs I just bought in dat stroker kit with Shovel jugs and prefer to keep it all Pan/PseudoPan.

Yeah, I hear that ... ^^

I've a few good Super B's with pump kits and am used to those, but how much would I be giving up HP wise ??

A bunch of ponies would be running on three legs if you used a Linkert carb ...

Ya just gained 26 more hungry cubes than what was there, that Super-B with a pumper is the perfect carb for the state of build your motor is headed ..

If needed, I got a S&S Pan manifold that is used ...

Can throw it in your pile of parts, if ya want it ??

... OR ...

Buy a new Panifold from Jason Phares ..

(and where in the powerband) running the M74 (or another and if so, which?) Linkert with that stroker kit? I've rebuilt a couple that didn't need much attention but never tuned one.

My interest is low end grunt and highway roll-ons, not high RPMs. What cam would best suit a two-wheeled tractor? It will be a solo bike and I like tall final drive gearing but I don't lug engines.

Later in the day I'll run a few Acc. Programs with diff. cam grinds, I'm more than sure we can pick a grind that will suit your needs ..

Box will be a late five speed in a Softail case (for the electric start, I can kick just fine but old age is ruthless and my ass might fall off without warning). Please put that Softail trans posted above in the Farmall pile. At that price there's no point in me hunting a Delkron case and buying the little shit to use my good splined shaft takeout. Like a sore dick, I can't beat it. The door chrome will be solved with kicker kit.

Can throw it in your pile of parts ... ??

Kinda thought you'd like that deal ... It's now belongs to you ...

Ya do know that 5th gear will need to be changed out from belt spline to a chain spline .... Be mighty hard to run a belt for final drive ...

And on the motor sprocket shaft if we run the 55-64 shaft it will be bout 3/8 of a inch short to line up with the 5-speed trans ...

We can get a 70-up special shaft that fits our needs ... That way there will be no need for attaining a special motor pully ..

As for threads maybe it would be better to tack my adventures onto this one for a Pan drivetrain MegaThread comparing options since the builds are similar.

....

....

Comment