Hi, I'm replacing the primary belt on my 79 shovel. I have the belt that BDL says is correct for my front and rear pulleys. My bike has the stock frame, and a cowpie tranny. I am also running an early shovel/pan round swingarm.

The belt has always been real loose even at max adjustment back, so I thought I'd figure out why.

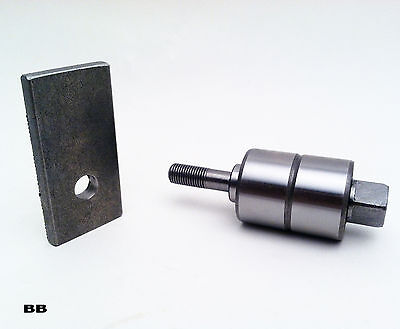

So the tranny is as far back as it can go, and the belt is still loose. The boss on the tranny that the primary/bearing support bracket bolts onto, is hard up against the swingarm. I'm not sure why?

I've tried the next size down belt (3 teeth smaller), but there's no way it will go on either.

Only thing I can think is that it's the combination of cowpie and round swingarm? Does anyone know if that primary boss on a cowpie has more meat on it than an older tranny? or if the OD of the round swingarm bigger than the square one, that would prevent the tranny from moving further back?

I'm thinking I'll have to scallop into that tranny boss with a grinder, but I'd rather not cos it's real close to the studs. Not sure what else to do to get the belt tight though?

Thanks for any ideas or help, apologies for the long post.

The belt has always been real loose even at max adjustment back, so I thought I'd figure out why.

So the tranny is as far back as it can go, and the belt is still loose. The boss on the tranny that the primary/bearing support bracket bolts onto, is hard up against the swingarm. I'm not sure why?

I've tried the next size down belt (3 teeth smaller), but there's no way it will go on either.

Only thing I can think is that it's the combination of cowpie and round swingarm? Does anyone know if that primary boss on a cowpie has more meat on it than an older tranny? or if the OD of the round swingarm bigger than the square one, that would prevent the tranny from moving further back?

I'm thinking I'll have to scallop into that tranny boss with a grinder, but I'd rather not cos it's real close to the studs. Not sure what else to do to get the belt tight though?

Thanks for any ideas or help, apologies for the long post.

Yeah shipping everything down here is brutal.. but you gotta pay the cost to be the boss I guess. I think I'll be able to rustle one up here. Will report back on how I go with it

Yeah shipping everything down here is brutal.. but you gotta pay the cost to be the boss I guess. I think I'll be able to rustle one up here. Will report back on how I go with it

Comment