I have some videos of ripping up and down the street before everything blew up

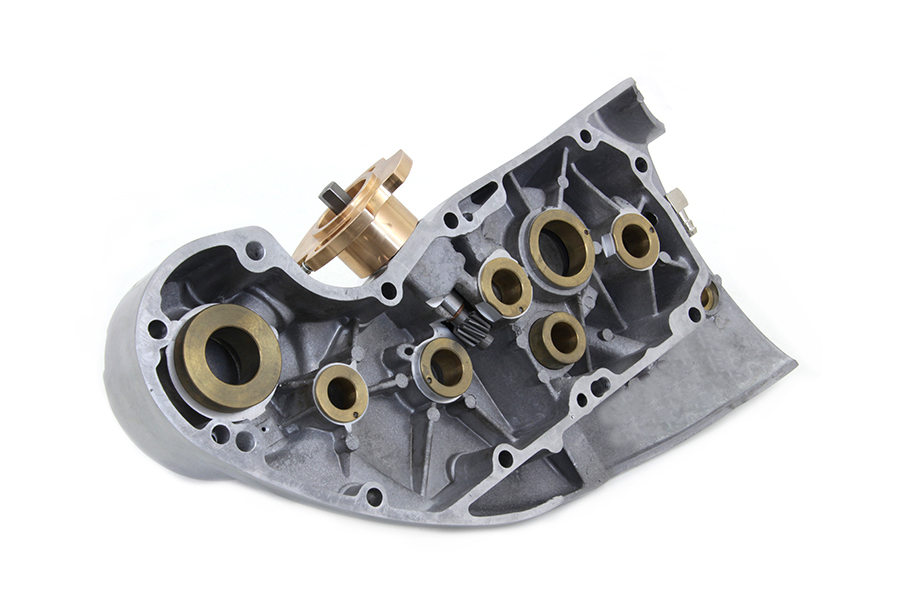

Ironhead cam bushings

Collapse

Desktop Ad Forum Top

Collapse

Mobile ad top forum

Collapse

X

-

-

Front exhaust cam gear you can see they’re in half decent shape

Cracked tappet block

Noticed some strange wear on pushrods looking like rings scraped into them or something idk if it was a valve adjustment thing or if they just got beat up when the wrist pin came out and everything was knocking around

I have a 2005 xl1200r as a daily so I’m ok on taking my time with the ironhead waiting for parts and stuff but it would be nice to get it running againLast edited by Cooldean69; 09-26-2021, 10:51 AM.Comment

-

Jim my parts book calls the dowel pin #271 is this interchangeable with part #275 dowel pin I can’t find a 271Comment

-

Bravo! You're so fucked. You've taken the first step on a long journey that will probably end in suicide.. Or at least a lot of screaming, and involuntary admission to a mental health facility.

If you have machining capacity, I saved money on reamers by using standard ones from and turning out a plastic insert (Delrin, I think? I can look if you're interested) to make them fit the case and work properly.

That saved a ton.

You can use a blind hole lap also. Which may even be better, because they're cheap and it leaves a better finish on the bushing with less burnishing when you're through. Use the same method of making them fit the case before you begin, of course.

Otherwise there's specialty tools all over the place. I've scored some pretty good deals on ebay.

Many times, a pilot bearing puller makes a cheap blind hole puller for other applications. Particularly for things like those cam bushings that don't require a lot of oomph to remove. Harbor Freight has a small blind hole puller set that would work fine for your application.

Look through the service manual before you begin this, though. There's the basic procedures and tools you'll need.

It takes a lot, actually. I did my shovel in house. First Harley I ever owned, or even rode, in my life. Never worked on one. Never did ANYTHING related to Harleys at all. And I have as much, or almost as much, in specialty tools as I do in buying the bike.

The people here know a lot. They're invaluable. Youtube is good too. I like "Tatro Machine" and his various exploits.

Look and learn, and be sure you want to do this yourself. It's a lot to come to terms with, even if you have excellent, non-Harley specific, skills. Experience, and a well equipped shop, generally.

Good luck.

Last edited by confab; 09-26-2021, 12:09 PM.

Last edited by confab; 09-26-2021, 12:09 PM.Comment

-

There’s a whole set of cam bushings these guys are selling online $120 with shims and pins so now it sounds like I need a blind puller and some reamers, drilling the holes for the pins seems like a pain in the ass I will have to read up on all of this some more

Would anyone on here trust harbor freight for measuring equipment like micrometer dial indicators etc.?Last edited by Cooldean69; 09-26-2021, 3:52 PM.Comment

-

being a hack/hamburger mechanic, I have threaded a tap in the bushing. then had a buddy hold down the cam cover and clamped a vise grip on the tap sideways and hammered on the vise grip. Ideal, no, but has worked on a few instances. Try not to break the tap. LOLComment

-

Not really..

But there's some good stuff on Amazon for cheap. Anytime Tools is the brand I got.

Not Starret, but it reviewed well and did the job. Read the reviews, where the real machinists use them and comment.

Most of the measurements are comparative, anyway. So the guy using the tool is more important than the brand of tool itself.Comment

-

Horror Freight? NO, get a few good measuring tools and they will last for the rest of your life. Starrett, Brown & Sharpe, Mitutoyo are the good brands, or if you are looking at vintage tools, add Lufkin and Federal. These really are LIFETIME tools, so the money spent will reward you forever. And there are piles of used machinist's tools everywhere, thanks to a lack of interest in the trade among the young.There’s a whole set of cam bushings these guys are selling online $120 with shims and pins so now it sounds like I need a blind puller and some reamers, drilling the holes for the pins seems like a pain in the ass I will have to read up on all of this some more

Would anyone on here trust harbor freight for measuring equipment like micrometer dial indicators etc.?

You can buy GOOD tools used for literally pennies on the dollar.

JimComment

-

DIY saved me tens of thousands, let me renovate my homes cheep, build my shops and keeps my overhead so low in retirement I have plenty of play money even as a crippled MSgt on disability. If I won the lottery I'd just live in a much bigger shop and the lottery cash would go even further.

It's not hard to build a better shop for yourself than most businesses have but it takes systematic research and utter determination including adjusting your life (like living where you can afford cheap rural acreage likely to stay that way) around wrenching and DIY (but that's all win so why not?). Shipping containers are terrific instant structures (don't buy junk trying to save money, that backfires. Post if you start looking and I'll enlighten thee).

A proper shop is the way to go before collecting more than two or three motorcycles or other projects since that cow will get you truckloads of milk. DIY let me and many other bikers maintain, repair and upgrade nearly everything we own and the payoff is impressive when you run the numbers. I never cried myself to sleep over buying quality tools, have never wanted a new vehicle with more than two wheels.

Start planning and learning EARLY. Even if ya rent or live in an apartment ya can have rollaways with non-marring casters (I just scored three surplus medication carts which even have built-on monitor arms and a place for a shop PC in back), a patient lift (non-marring casters, fits through standard doorways) and plastic industrial carts (narrow works best indoors, I use mine for a printer cart and others for electronic work). The neglected key to quickly and easily having a nice workspace in small spaces is rolling indoor storage that's easy to keep clean, and me being me I always look for solutions. Rolling storage and rolling everything else works great in conventional shops too which is why most USAF tool boxes roll and it's easy to fab angle steel dollies with large, effective casters to roll on pretty much everything. I mention this because since OP is starting out he will have much less to figure out knowing this in advance.

Collect ramps too. Large aluminum U-haul and other delivery truck ramps are worth the money and shit all over lesser ramps in big runny streams. They're light enough (you can add handles easily if desired) to carry single-handed and easy to clean.

Effective storage is glorious. I came up when it was normal of bikers with little money to have shitty storage and just buy tools. Bad idea since storage can be had cheap. Storage is an effectiveness multiplier as are work carts which are readily available used (Fecesbook Marketplace is a good source). An industrial plastic cart contains oil, small parts etc and is easy to clean. Collect stainless containers (like restaurant steam table accessories) for lifetime parts cleaning etc.

Everyone needs a good vise stand and used Ridgid tristands can be had for about 150-200 with a working chain vise. Mount a bench vise to some thick pipe and now you have a rotating mobile bench vise that's easily mobile and can store in a closet.

I managed 1-1/2 Ironheads plus tools in my military dorm lockers. It's never too early to grow your workshop.

A good way to not chase your Ironhead around a workbench is a Harbor Freight engine stand. While an Evo bolts to the flat stand head plate by adding a couple holes, Ironhead rear mounting can require grinding some relief. Easy with a flap disc (flap discs are fucking wonderful) on an angle grinder and will be self-explanatory. A lifting arm can pick your motor complete or partial without you getting a hernia (hernias suck) and is cheap to make even if ya buy the steel. This one clears complete Sporty engines with enough room for top end swaps:

Patient lifts are very cool small cranes with spreader bars for lifting immobile patients out of bed. I always wanted one but many are rented (a rip off) and paid for by insurors. They are worth looking for because not only are they a nice precise utility hoist but the leg spread is adjustable which lets you easily get them

BTW one way to get versatile is work part time at a multibrand shop. Indies who fix all the old shit dealers don't touch learn many useful things (and see more horrors than a mortician in a leper colony but shit be like that sometimes). Many of us old fucks began that way and it pays off educationally. You learn how businesses survive hard times and how to provide the social and mechanical mix that sustains independent bike shops. That shit ain't easy but when it works ya get customers for life.Comment

-

Oh, I totally agree..

I know people who make really good money, but always seem to be in trouble because they have no DIY ability and pay through the nose for simple things most of the rest of us wouldn't think twice about doing ourselves. I mean, stuff that's not even a "job" job. It is really amazing just how much money that eats up. And that's for normal endeavors in their daily lives. If you're into old bikes? Forget about it. You better have a stack of cash or be handy with the tools. Hiring indies here costs you dearly, and there's nobody doing it well that I've seen. (Barely anyone doing it at all, actually.) So, you'll pay them a fortune AND get an inferior job for your investment.

And it's not as rewarding, ya know? Part of the satisfaction of an antique anything is doing it yourself. This is doubly true of choppers because, like you say, they're rolling folk art. They are art. If you didn't do at least some of it yourself? You're kind of relegated to wannabe status and someone who who can just buy a bunch of leather, move the handlebars bars and twist the throttle. Fun. But you're not a "biker" like the bikers I knew growing up. Those guys knew their bikes inside and out.

Tool carts are fabulous. I love the stainless hospital stuff. A customer saw me building my first tool cart and came back in with a stainless hospital shelf from something or other. It was perfect for the top. I still have it. It's the Harley cart now. Those things are fabulous, because you can do your Harley stuff on it and just cover it up and roll it out of the way when you need to do something else and get back to it later. I bought a blue point cart for the tools I use a lot, and the rest stay in the box. It is so nice to be able to drag them over to your job and not spend all day running back and forth. The Harbor Freight big box is a deal, and it holds a ton. Really hard to beat for the money. (Although you should probably chain it to the wall for safety.)

I never saw a patient lift. That's a great idea. Everyone needs some kind of lifting ability. Even if it is a folding engine hoist. Hydraulic lift tables are awesome and they're not horribly expensive. I use mine daily. Car lifts are dirt cheap now. Good ones can be had used for a thousand bucks and less. These have motorcycle applications also.

If op wants to build a tool nest for his bike? There's so much stuff out there now, and for practically nothing. Machine tools. Hand tools. Lifts and hydraulics of all kinds. Between auctions and facebook, and the ability to research tools and specs on the internet? You can do this so much cheaper and better today than ever before. It's truly a buyer's market for these things. Locating parts is so much better with the internet.

Agree.. Anyone can get into this so easily now if they want. It's a completely different world for projects and knowledge than it was growing up.Comment

-

I use a slide hammer with a customized hook to yank the bushings, no problem. Worked at a buddy's shop where we had some of jims drill jigs and the proper reamers and an old case half with bearings in it.

If you have all that it's a few hours work.

If you don't, that $300.00 piece would be looking pretty good.Comment

300 mobile ad bottom forum

Collapse

Comment