Are bearing supports always used, no matter if you're running wet or open belt clutch? my set up is going to be a 1.5" belt in a repop panhead tin and not sure if I need to have that bearing support on the backside of the inner tin or not. This will be on a ratchet top trans with a cone shovel

As for alignment, does everyone use this kit or something similar?

As for alignment, does everyone use this kit or something similar?

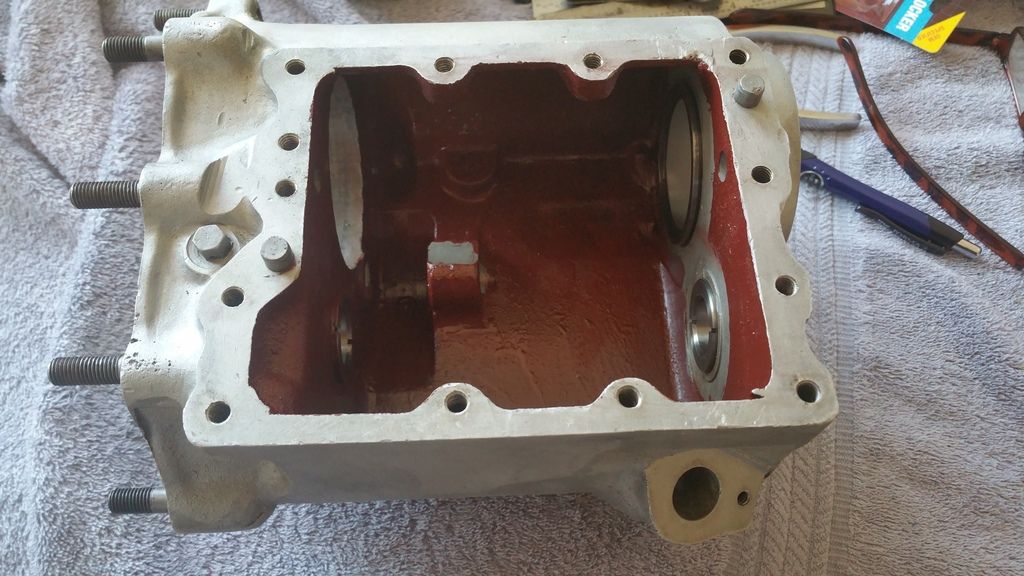

Comment