Hey Guys,

Done a decent amount of research on this, I just want some confirmation/ideas before I try this again.

1977-ish 4 speed ratchet top trans, BDL open belt primary, brand new 5 finger hub, brand new clutch plates

So - was riding my newly built chopper and clutch lever goes slack (foot clutch) and I cant disengage clutch. This was sketchy as hell and hard as shit to stop.

Got it to the shop, via a tow, and was able to open it up. Throwout bearing (wafer style) was toast, probably due to me being an ape in tightening adjustment screw too much. Okay, so got new Throwout Bearing parts in. Took a bit to get off the old clutch pushrod because it had welded to the adjuster screw. I got those apart and proceded to install new stuff.

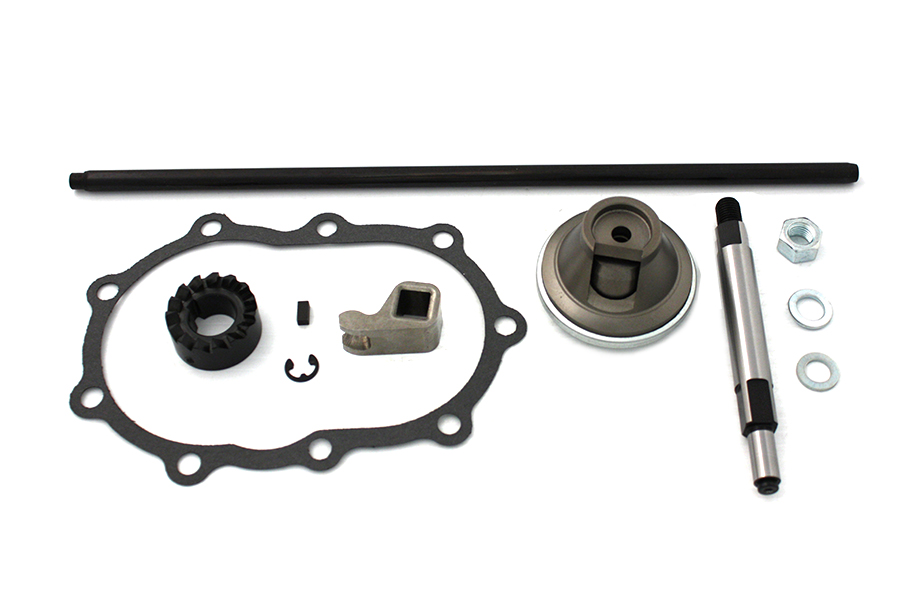

Now - my new throwout bearing kit from jpcycles, came with a brass ring, and 2 small steel bushing things. Does anyone know what those are for? The small steel bushing things are maybe a 1/2" in length and fit perfectly around the clutch pushrod. Needless to say, I didn't use that shit cause I didn't know what it was for. https://www.jpcycles.com/product/630...ut-bearing-kit

they're in that pic

So anyways, I didnt get a new adjuster screw - so I used the old one that had been welded to the old pushrod. Installed new throwout bearing stuff, put in oil, started up, did some clutch tests and boom - welded again. throwout bearing looks fine - I made sure I didn't adjust tight at all - was honestly pretty loose just cause I was scared I'd tighten too much again. So after some effort, I was able to get the fused adjuster screw and new pushrod unstuck. Obviously at this point I'm pissed and trash everything.

So - could my old adjuster screw really fuse within 30secs of contact with the new pushrod? I see some forums saying they hardened that end? So I guess after it had already fused once, it is toast forever?

My pushrod sticks out of the oil seal when it contacts the adjuster screw, so since this is a dry set-up, I dpn't see how it'd ever get lubrication - at the end of the day it will always be metal to metal correct? I am now buying the adjuster screw with the ball at the end of it to help with non-welding.

Ultimately all this is to ask - what can i do to make sure this shit doesn't fuse again? The pushrod pokes out of the oil seal on the clutch side, and it's dry clutch so it will always be unlubed. I got a new adjuster screw and pushrod so that's good right? I won't tighten too much, so that they aren't under stress the entire time - only when I am pressing down clutch lever.

I understand I am to adjust the clutch adjuster til the shift arm has no play, then back off so that it has some play. Then I put on my foot clutch chain, and adjust that. when my foot clutch chain is attached, should it have slack with the shift arm? The foot clutch lever has weight to it, so I'm worried that it is pulling the shift arm, therefore turning the finger and pushing the rod into the adjuster - however that's really low pressure, so that should be fine right?

Also there was some wear on the oil slinger, with the throwout bearing pushed all the way to the finger, it seems the oil slinger would actually rub into the finger - that doesn't seem cool.

Any ideas would be great. just tired of frying new parts and want to not do it yet again. Could that fried adjuster screw being reused really have been the crux of my issue? Rewelding within 30secs sounds unbelievable though.

Done a decent amount of research on this, I just want some confirmation/ideas before I try this again.

1977-ish 4 speed ratchet top trans, BDL open belt primary, brand new 5 finger hub, brand new clutch plates

So - was riding my newly built chopper and clutch lever goes slack (foot clutch) and I cant disengage clutch. This was sketchy as hell and hard as shit to stop.

Got it to the shop, via a tow, and was able to open it up. Throwout bearing (wafer style) was toast, probably due to me being an ape in tightening adjustment screw too much. Okay, so got new Throwout Bearing parts in. Took a bit to get off the old clutch pushrod because it had welded to the adjuster screw. I got those apart and proceded to install new stuff.

Now - my new throwout bearing kit from jpcycles, came with a brass ring, and 2 small steel bushing things. Does anyone know what those are for? The small steel bushing things are maybe a 1/2" in length and fit perfectly around the clutch pushrod. Needless to say, I didn't use that shit cause I didn't know what it was for. https://www.jpcycles.com/product/630...ut-bearing-kit

they're in that pic

So anyways, I didnt get a new adjuster screw - so I used the old one that had been welded to the old pushrod. Installed new throwout bearing stuff, put in oil, started up, did some clutch tests and boom - welded again. throwout bearing looks fine - I made sure I didn't adjust tight at all - was honestly pretty loose just cause I was scared I'd tighten too much again. So after some effort, I was able to get the fused adjuster screw and new pushrod unstuck. Obviously at this point I'm pissed and trash everything.

So - could my old adjuster screw really fuse within 30secs of contact with the new pushrod? I see some forums saying they hardened that end? So I guess after it had already fused once, it is toast forever?

My pushrod sticks out of the oil seal when it contacts the adjuster screw, so since this is a dry set-up, I dpn't see how it'd ever get lubrication - at the end of the day it will always be metal to metal correct? I am now buying the adjuster screw with the ball at the end of it to help with non-welding.

Ultimately all this is to ask - what can i do to make sure this shit doesn't fuse again? The pushrod pokes out of the oil seal on the clutch side, and it's dry clutch so it will always be unlubed. I got a new adjuster screw and pushrod so that's good right? I won't tighten too much, so that they aren't under stress the entire time - only when I am pressing down clutch lever.

I understand I am to adjust the clutch adjuster til the shift arm has no play, then back off so that it has some play. Then I put on my foot clutch chain, and adjust that. when my foot clutch chain is attached, should it have slack with the shift arm? The foot clutch lever has weight to it, so I'm worried that it is pulling the shift arm, therefore turning the finger and pushing the rod into the adjuster - however that's really low pressure, so that should be fine right?

Also there was some wear on the oil slinger, with the throwout bearing pushed all the way to the finger, it seems the oil slinger would actually rub into the finger - that doesn't seem cool.

Any ideas would be great. just tired of frying new parts and want to not do it yet again. Could that fried adjuster screw being reused really have been the crux of my issue? Rewelding within 30secs sounds unbelievable though.

Comment