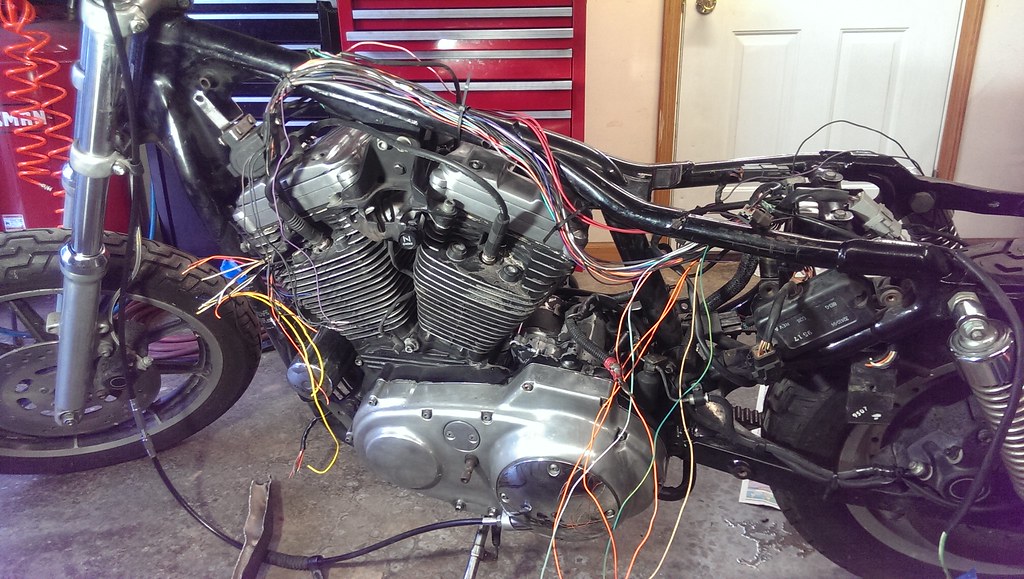

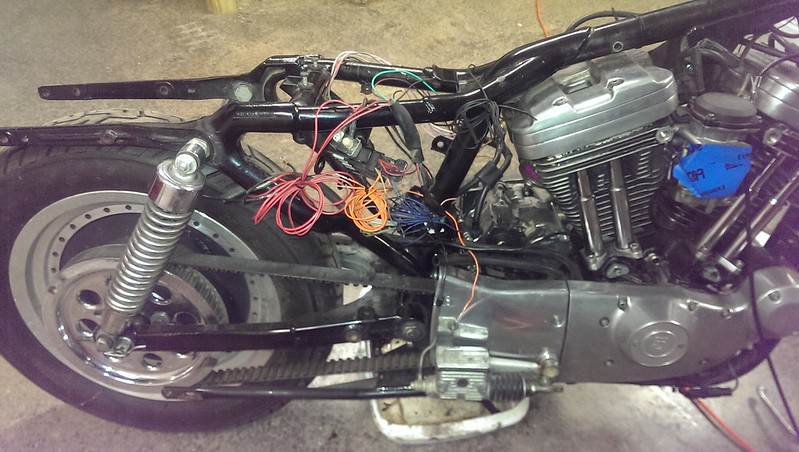

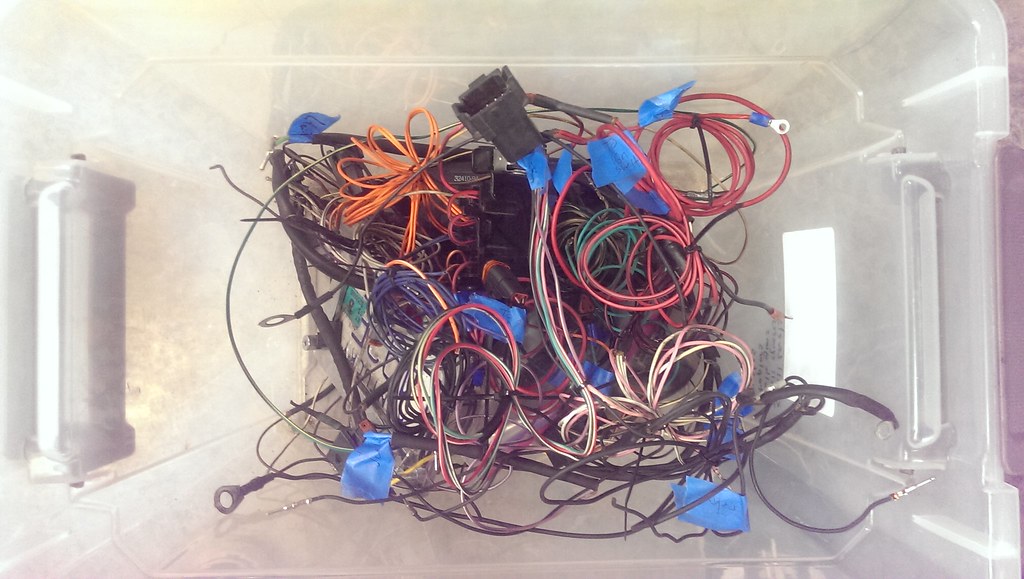

I am the third owner, my PO bought it from the original owner (who was a friend of his) about 4.5-5 years ago. My PO took it apart about a year and a half ago after gas spilled on the tank and ruined the paint. He intended to repaint and add a wide tire kit, but one thing led to another and neither of those things happened.

The original owner was a big fan of chrome and accessories and I am not. I am a keep it clean and simple sort of guy so a lot of the first part of this project is going to be undoing much of what the two PO's did.

The original owner did put in a 1200 kit with Andrews N2 cams,which is nice.

If this looks familiar, I also have a thread running over at XL F. The first few posts here will be cut and pasted from that thread to get up to the present. Let me know if that's not cool and I'll cease and desist.

The original owner was a big fan of chrome and accessories and I am not. I am a keep it clean and simple sort of guy so a lot of the first part of this project is going to be undoing much of what the two PO's did.

The original owner did put in a 1200 kit with Andrews N2 cams,which is nice.

If this looks familiar, I also have a thread running over at XL F. The first few posts here will be cut and pasted from that thread to get up to the present. Let me know if that's not cool and I'll cease and desist.

Comment