Can you post a few photos of the clutch lever arm that's in the kick cover and bearing... ???

More shovelhead clutch problems

Collapse

Desktop Ad Forum Top

Collapse

Mobile ad top forum

Collapse

X

-

Your clutch finger looks to be not the right one for being used on the witch hat bearing ....

This is the one that H-D used on the 41 to 74 models...

VT No: 17-1509

OEM No: 37070-39

Clutch release finger.

Fits:

FL 1941-1974

FX 1971-1974

UL 1941-1948

But as long as the pushrod doesn't stick out of the bearing I don't see a problem using what you have...

Got another question about the fit of the bearing to the kicker clutch gear.... Is it super loose ??

The 75 gear was made with a smaller O.D. than the 74 and back gears being the pushrod was being guided by a bushing in the mainshaft.... The early witch hat bearing was the guide for the pushrod therefor no bushing was used in the shaft...

Another potential problem with swapping parts around with early and late is the kick cover on the later models not having room for the witch hat bearing to work well... They limit the throw greatly...Last edited by Dragstews; 04-28-2017, 10:49 PM.Take my 45 and outrun em all ..Comment

-

I wouldn't call it a precision fit, but the id/od are relatively close.

Pushrod doesn't stick past the bearing, and this all was working without a hitch. Something went wrong the last time I had the basket off, had it off probably a dozen times without turmoil.Last edited by Guest; 04-28-2017, 10:50 PM.Comment

-

I'd be double checking everything with that clutch basket first....

Did ya inspect the clutchplates when the basket was off?

Do they still have the stock anti-rattle ball and spring deals riveted to the steels? They can come loose and get stuck between the plates.

Did you get the diaphram spring shimmed correctly? If it gets over flattened it may stick.

Are the clutch hub bearing clips installed correctly? If the basket is walking on the hub...Comment

-

no balls all plates for the rivera pro, maybe 1k miles on it, still look new.

Took measurements on the basket against fixed object, it's not moving. Bearing/hub is fully assembled.

Haven't checked spring height, it's near new Rivera suggests it's not necessary, but I will, running out of options.Comment

-

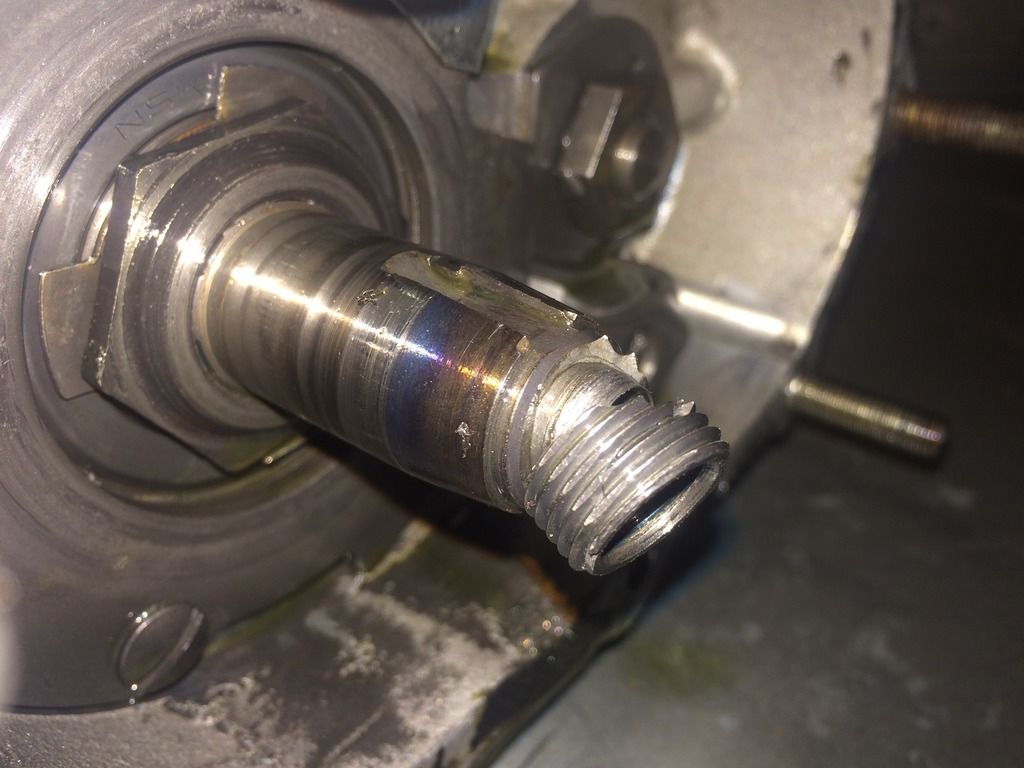

Where the broken end of the shaft is where the bushing will be at on the 75-up mainshafts...

Might check to make sure that the ball bearing nut on the shaft is tight and the four retainer screws ....

Something is walking (Lost motion) in order for the clutch to act the way it is...Take my 45 and outrun em all ..Comment

-

Yeah no tolerance for a bushing between the pushrod and mainshaft it would be paper thin.

everything in the kicker cover is still tight, tabs bent over. The basket didn't move, absolutely sure, if the basket stayed put so did the mainshaft. so figured it had to be in the throwout end, but I didn't find anything my eyes could see.

Diaphragm spring is a little slack, .030-.040 instead of the .010-.020. Works just fine when the cable hasn't gone slack. I'll throw some shims in there and hope the r/i magically made something mesh correctly again.Last edited by Guest; 04-29-2017, 10:02 AM.Comment

300 mobile ad bottom forum

Collapse

Comment