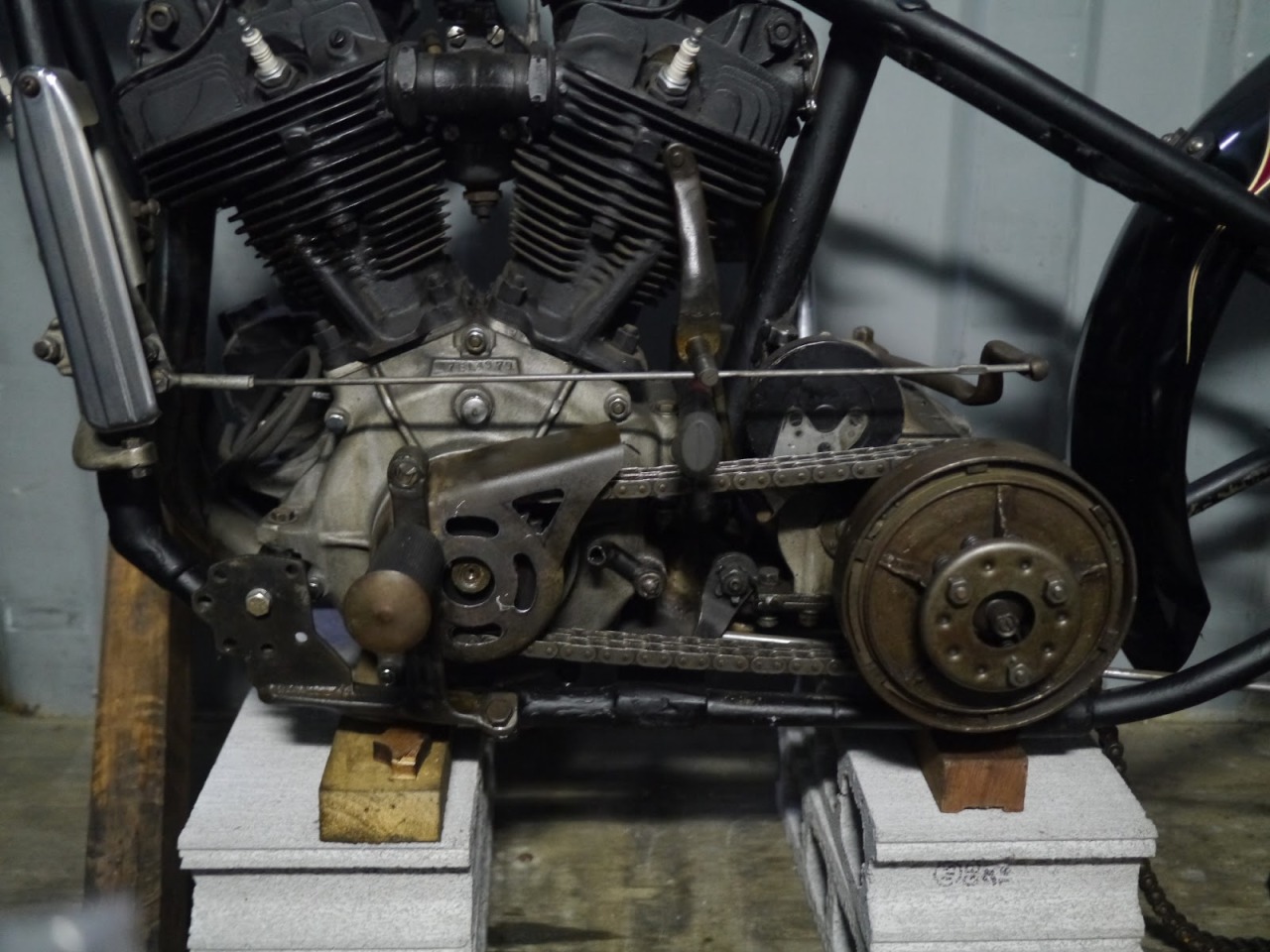

I've thought about that solution (swingarm mounted fender) but for some reason every example bike I see that on doesn't look right to me. The "flow" from the rear section onto the fender/wheel is all broken up and it just looks like poop. Or it looks like they're trying to look too much like a hardtail.

And I like the kinda jaunty hillclimber fender mounting anyhow, with some good air gap between the tire and tin. And I'm just adding another thing to the dependency chain as noted before... gotta get the swingarm mounted to get the wheel mounted after getting the tire fitted before I can get the fender positioned before starting on the seat to establish the rider position to I can get to re-attaching the floorboard.

Choppers man.

And I like the kinda jaunty hillclimber fender mounting anyhow, with some good air gap between the tire and tin. And I'm just adding another thing to the dependency chain as noted before... gotta get the swingarm mounted to get the wheel mounted after getting the tire fitted before I can get the fender positioned before starting on the seat to establish the rider position to I can get to re-attaching the floorboard.

Choppers man.

Comment