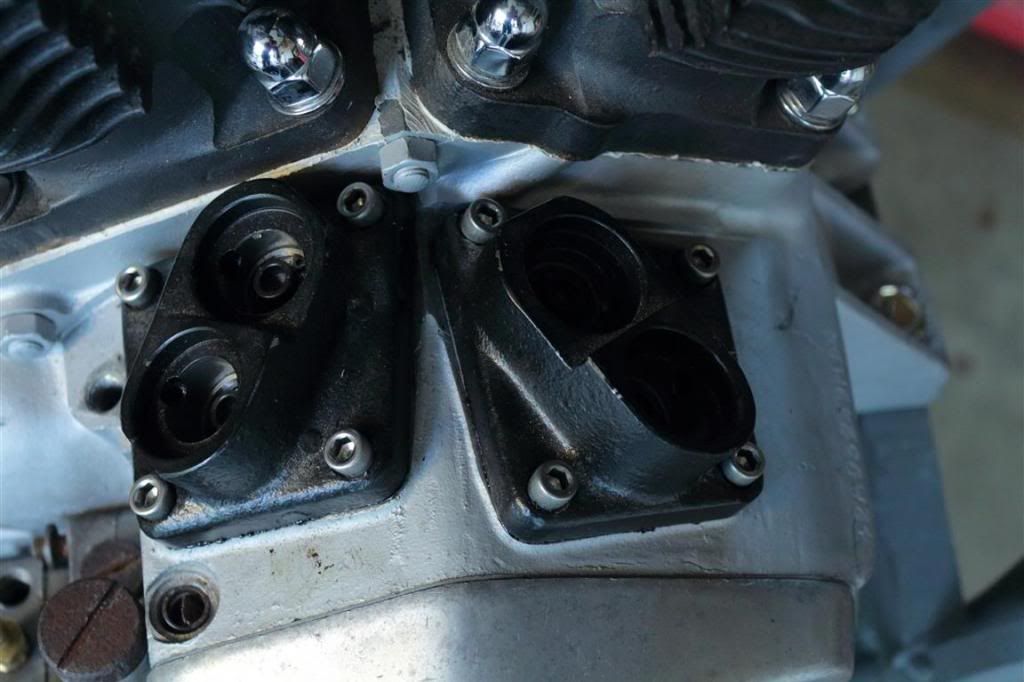

I picked up the engine from the shop yesterday. It seems the oil pump rebuild kit I had been given had the wrong sized parts in it; the shop got it sorted and it's now assembled and good to go. I watched a few YouTube videos in the interim and learned how to disassemble conventional fork legs. I had NO clue it was actually so friggin' easy. I've ordered new seals for the lowers and will likely assemble them in the coming weeks; going on vacation soon and won't be able to finish until after that's done.

I'll just use the legs I have now until I get the whole bike built to see if the length will work. No being able to roll the lift under the bike isn't that big a deal right now.

I'll just use the legs I have now until I get the whole bike built to see if the length will work. No being able to roll the lift under the bike isn't that big a deal right now.

Comment