makeing forward controls

Collapse

Desktop Ad Forum Top

Collapse

Mobile ad top forum

Collapse

X

-

-

-

You plan on pressing bearings onto some tube, I always start with one inch tube, then get the next size up, that fits right over the one inch tubing, and use that for the shifter and brake pedal rings. I understand if you want really clean set ups, but this is for jap crap chops? No? I do one thing that is pretty nice after the forwards are completed, I then cover the foot pegs with my leather, and cut some deep grooves into the leather before stitching them onto the pegs, I try to get others to do this as well, they all act as if I should do it, and they try to throw money at me, I am trying to spread the abilities of leather werxing, and I got no bites, even though I am using leather bait and needle hooks, no bites!!!!! Even though, these are jap crap chops, and most of my werx is industrial, it has a bit of artzyness to it!! Am I trying to hard at this???? I no unnerstan!!!!Comment

-

Swinewerx, You got Pics of your work? I'm interested. Btw, my jap ain't crap.You plan on pressing bearings onto some tube, I always start with one inch tube, then get the next size up, that fits right over the one inch tubing, and use that for the shifter and brake pedal rings. I understand if you want really clean set ups, but this is for jap crap chops? No? I do one thing that is pretty nice after the forwards are completed, I then cover the foot pegs with my leather, and cut some deep grooves into the leather before stitching them onto the pegs, I try to get others to do this as well, they all act as if I should do it, and they try to throw money at me, I am trying to spread the abilities of leather werxing, and I got no bites, even though I am using leather bait and needle hooks, no bites!!!!! Even though, these are jap crap chops, and most of my werx is industrial, it has a bit of artzyness to it!! Am I trying to hard at this???? I no unnerstan!!!!

Bobull, you lost me too. And I want to unnerstan!Comment

-

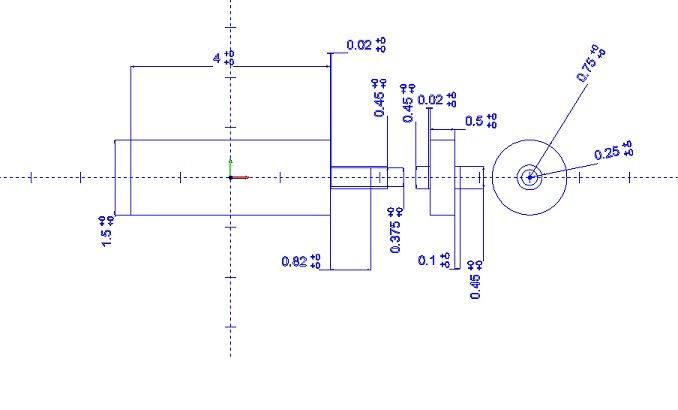

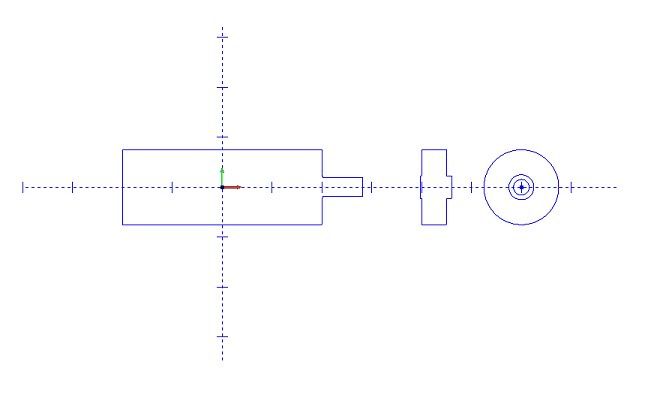

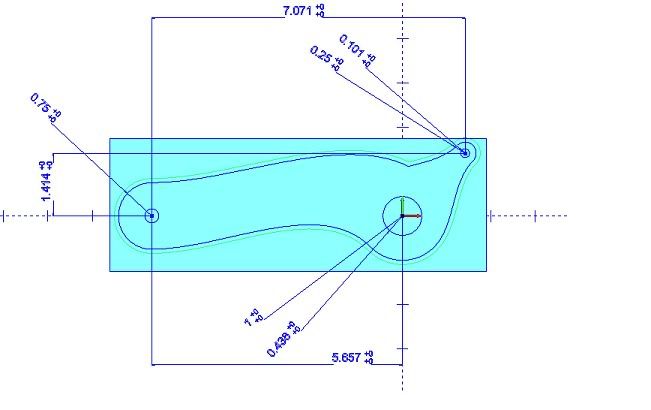

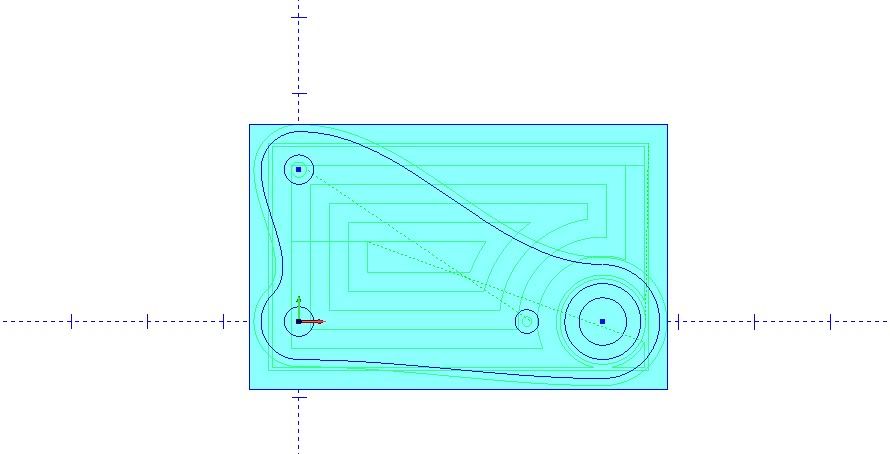

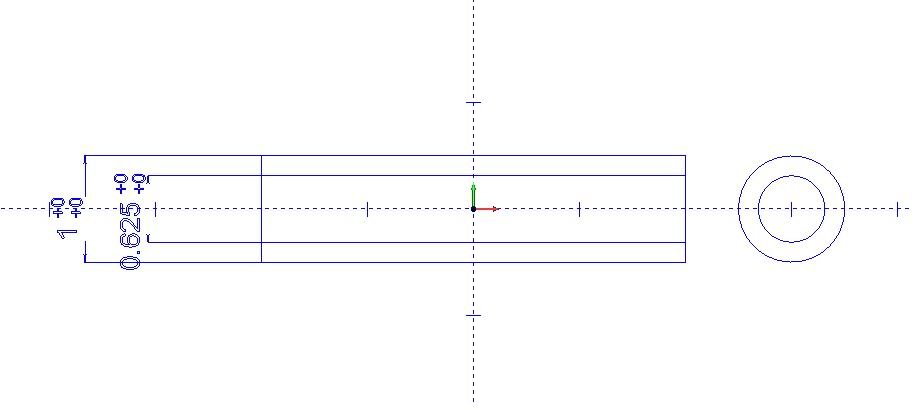

ok well first I was going to make all the part out of 6061 aluminum. I am planning on pressing a bearing in to the .438 R of the 3rd pic. the bearing has a .375 ID and that is going to be pressed on to the .375 OD of pic 1. the circle to the right of pic 1 is going to sandwich the swing arm. pic 4 bolts to the frame. pic 5 will press onto pic 4Comment

-

Why yes I do!!! The only reason I call them crap, is because all the hardley people call them that! So, I made it my decision to keep that type of name for my choppers!!! I guess I am trying to pull the reverse psychology thing on them! Kinda like my name!! I was called pig! Fat slob!!! Filthy swine! all the names that would normally hurt a person and make them boo hoo! I took that filthy name and made it really a part of me!!! I take all negative things and change them into positive things!!!! If you were close by, you could see all of our chops and bikes, and how I went way over board with the leather werx, as well as the welding, and last of all, paint!! although, I have changed my ways with paint, and I now lean on flat colors, like primer instead, I still have some cool paint jobs, but only on her bikes, not her chop!!! I had changed the time consuming methods of painting really nicely to flat colors!!! They are better to maintain, as in, no worries if I scratch or dent anything! anymore!!! this is the best viewed one, it does have a bend in the left side peg, because I was excited after putting in the third motor, and I was very medicated and I took a right turn too sharp, and it and I landed on the pavement! Since it is not that bad of a bend I did not cut off and reweld! since I do all my own welding, it is not that important to get done all that fast!!!!

there are some rough spots, only because after I had my external fixating halo removed from my right leg, I then quickly removed the extended foot pegs as well as extra bars that would keep my right leg in an upward position to help releive the fluid that would cause my right leg to balloon way out!! I have not ground off the stubs as well as the stubs that are now underneath the foot pegs that had exteneded foot pegs, I just recovered the foot pegs with new leather, and figured that the stubs would help keep the leather on the pegs, I have lost foot peg leather covers due to slopping used motor oil on the pegs to keep them lubed when I slop it on, it appears that even silcone gives way after a while with all the slop from my lubing techniques!!! On the long chopper, the vision of what is done is better, I use one inch tubing, then the next size up that slips over the one inch tube, I then cut the slippable tube into four very slender rings, then two wider rings, the wider rings are what will be moving on the one inch tubing, which will then have the shifter and the brake pedal welded onto the wider rings, I first put a very slender ring in place as to where I want the shifter to be, and weld the out side edge of the slender ring all the way around,and I do not weld the inner side of the very slender ring,I want my pegs and shifter to move, and welding both side could possibly stop the shift and pedal from having motion. then, I slip the wider ring up against the welded slender ring, then slide the next very slender ring up against the wider ring, and weld that very slender ring pretty tightly up against the wider ring, but only welding the outside edges of the very slender rings, you want the wider ring to be able to spin for now, after that is all welded up, the verty slender of rings, and you have the wider ring able to spin when you push with you pliers, then you weld on your shifter, also, this is when you decide whether you will have the linkage above the foot peg, or below, I traditionally put the linkage for the shifter below the peg. then you will have to weld on a tab with a hole drilled into it for the linkage, I usually use quarter inch steel rod that I bend to a ninety degree tilt, and drill eighth of an inch holes into the bent linkage rod, also making sure that you make your linkage long enough to shift and not go to far, length is very important here! I then take the stock shift lever and cut off the teenie peg, and then have a straight shaft for a shifter, I then drill a quarter inch hole into the shaft and put in the linkage all the while I drill an eighth inch hole into the linkage rod, and then after placing the linkage in the holes that are exactly the rods size, I put a washer on the linkage as well as a cotter pin, it is best to carry a few cotter pins that are new, never reuse them!!!and carry washers aslo!!! If anybody is near the area of Lodi, california, and would like to have a a live view of all these things, please come by!!! I do not care if anyone copies things I do, or just gets inspired by what I do but change it all together! I have seen a different type of linkage end that is rather clean looking, but, I always do what I can with what I have and that is simple to work with!! I do have to caution anyone who does come to see what kind of mess I do, you might get a bit inspired!!!! especially when it comes to leather work, and me, the way I do it, is pretty crazy, but legal!!!!!

there are some rough spots, only because after I had my external fixating halo removed from my right leg, I then quickly removed the extended foot pegs as well as extra bars that would keep my right leg in an upward position to help releive the fluid that would cause my right leg to balloon way out!! I have not ground off the stubs as well as the stubs that are now underneath the foot pegs that had exteneded foot pegs, I just recovered the foot pegs with new leather, and figured that the stubs would help keep the leather on the pegs, I have lost foot peg leather covers due to slopping used motor oil on the pegs to keep them lubed when I slop it on, it appears that even silcone gives way after a while with all the slop from my lubing techniques!!! On the long chopper, the vision of what is done is better, I use one inch tubing, then the next size up that slips over the one inch tube, I then cut the slippable tube into four very slender rings, then two wider rings, the wider rings are what will be moving on the one inch tubing, which will then have the shifter and the brake pedal welded onto the wider rings, I first put a very slender ring in place as to where I want the shifter to be, and weld the out side edge of the slender ring all the way around,and I do not weld the inner side of the very slender ring,I want my pegs and shifter to move, and welding both side could possibly stop the shift and pedal from having motion. then, I slip the wider ring up against the welded slender ring, then slide the next very slender ring up against the wider ring, and weld that very slender ring pretty tightly up against the wider ring, but only welding the outside edges of the very slender rings, you want the wider ring to be able to spin for now, after that is all welded up, the verty slender of rings, and you have the wider ring able to spin when you push with you pliers, then you weld on your shifter, also, this is when you decide whether you will have the linkage above the foot peg, or below, I traditionally put the linkage for the shifter below the peg. then you will have to weld on a tab with a hole drilled into it for the linkage, I usually use quarter inch steel rod that I bend to a ninety degree tilt, and drill eighth of an inch holes into the bent linkage rod, also making sure that you make your linkage long enough to shift and not go to far, length is very important here! I then take the stock shift lever and cut off the teenie peg, and then have a straight shaft for a shifter, I then drill a quarter inch hole into the shaft and put in the linkage all the while I drill an eighth inch hole into the linkage rod, and then after placing the linkage in the holes that are exactly the rods size, I put a washer on the linkage as well as a cotter pin, it is best to carry a few cotter pins that are new, never reuse them!!!and carry washers aslo!!! If anybody is near the area of Lodi, california, and would like to have a a live view of all these things, please come by!!! I do not care if anyone copies things I do, or just gets inspired by what I do but change it all together! I have seen a different type of linkage end that is rather clean looking, but, I always do what I can with what I have and that is simple to work with!! I do have to caution anyone who does come to see what kind of mess I do, you might get a bit inspired!!!! especially when it comes to leather work, and me, the way I do it, is pretty crazy, but legal!!!!!

Comment

-

Lets also keep in mind, I am not trying to sell my services, I was not aware I had services, and I am not trying to force anyone to have what I have!!! nor hi jack this thread, I will and am however attempting to trying to get people to do all work that they want, as in, start making things and cover them with leather, weld things, and paint too, but the paint thing, is really not soo important when a person, likes his bikes and choppers to be really dirty with gear oil, that collects dirt and things making it look like black velvet. I always laugh at the people who are really cleaning there bikes, and spend about a couple hours doing so, while I just got on and ride! sometinesI will return from a ride whether it is a short one, or a couple hours of a ride, and the person who was cleaning there bike, is still cleaning!!!! This is why I love durtee bikes and chops!! Also, I never see anyone with a chopper, onlky stock bikes, I have known one guy who called his bike custom, only cuz hardley said it is, not custom when there are thousands just like it!!!!!! this red one is difficult to see, I welded the forwards on to the down tubes, which actually hides them in photographs, if you want to see all that I own and find worthy of taking photos of, go to my facebook, it is, swinewerx kelley I am lacking two of the bikes that came back, although the burgundy shadow came back as well, three came back and I find it hard to believe that they came back like boomerangs. I have come to the realization that I cannot even give away bikes for free, or with 500.00 plus a bike, they all return, but without the 500.00 I am planning on non opping the bikes I very rarely ride!!! I mostly ride my lobgest chopper, then my shortest chopper, then my in the middle chopper, the one in this thread is my middle sized chopper, then my burgundy shadow, is last!!! I would really like to know if it is because my bikes and choppers are total junk!!! They all keep coming back!!!! and thye usually hurt when they come back, the registration, is way past due, and the fines and such add up to around 500.00, what I gave the last three people with each bike, Or am I just way too nice??

this red one is difficult to see, I welded the forwards on to the down tubes, which actually hides them in photographs, if you want to see all that I own and find worthy of taking photos of, go to my facebook, it is, swinewerx kelley I am lacking two of the bikes that came back, although the burgundy shadow came back as well, three came back and I find it hard to believe that they came back like boomerangs. I have come to the realization that I cannot even give away bikes for free, or with 500.00 plus a bike, they all return, but without the 500.00 I am planning on non opping the bikes I very rarely ride!!! I mostly ride my lobgest chopper, then my shortest chopper, then my in the middle chopper, the one in this thread is my middle sized chopper, then my burgundy shadow, is last!!! I would really like to know if it is because my bikes and choppers are total junk!!! They all keep coming back!!!! and thye usually hurt when they come back, the registration, is way past due, and the fines and such add up to around 500.00, what I gave the last three people with each bike, Or am I just way too nice??

Comment

-

Sorry about sending swinewerx off on a rant. His leatherwerk is cool tho.ok well first I was going to make all the part out of 6061 aluminum. I am planning on pressing a bearing in to the .438 R of the 3rd pic. the bearing has a .375 ID and that is going to be pressed on to the .375 OD of pic 1. the circle to the right of pic 1 is going to sandwich the swing arm. pic 4 bolts to the frame. pic 5 will press onto pic 4

So what's the bike look like now? That's some heavy duty planning you've got. By bearing do u mean bushings? And are these fwd or rear sets? Cuz you mentioned a tow bar and swingarm mount. Anyway...show us the bike.Comment

-

Study "simple linkage mechanisms"]. Tubes, tabs, holes and bushings are easy.

Study the high dollar billet controls for some of the cool tricks they use (most of their linkages are quite simple), then remember billet and plate aren't very expensive and you can (and many bikers have) work aluminum with very basic tools. Of course steel is easy.

Your local metal supplier should have some inspiring round bar, plate etc cutoffs for cheap. Your local hardware store often has brass bushings (don't run steel on steel).

Study Heim joints, rod ends and turnbuckles. Lots of that hardware including aircraft surplus is available via Ebay.

Cutoff shift levers can have whatever fitting you wish welded to the end. For example you can drill and tap round bar to fit a Heim joint, weld in place, then chase the threads with a tap after welding (many forget this) and have a dirt cheap shift link you can connect to whatever.

Study stuff like footpeg mounts. Dyna mounts with two bolts are easy to make mounting blocks for. Weld block to frame and you've one route to mids.

Make a folder for linkage pics and burn lots of evening hours saving pics of different parts, including cafe racer rearset controls because some of those are pretty slick.Comment

300 mobile ad bottom forum

Collapse

Comment