Friday, 10 February 2012 - Kick it, kick it good!

Well it's been sometime since my latest update. Things are slowing down due to funds and electrical parts taking their time to arrive.

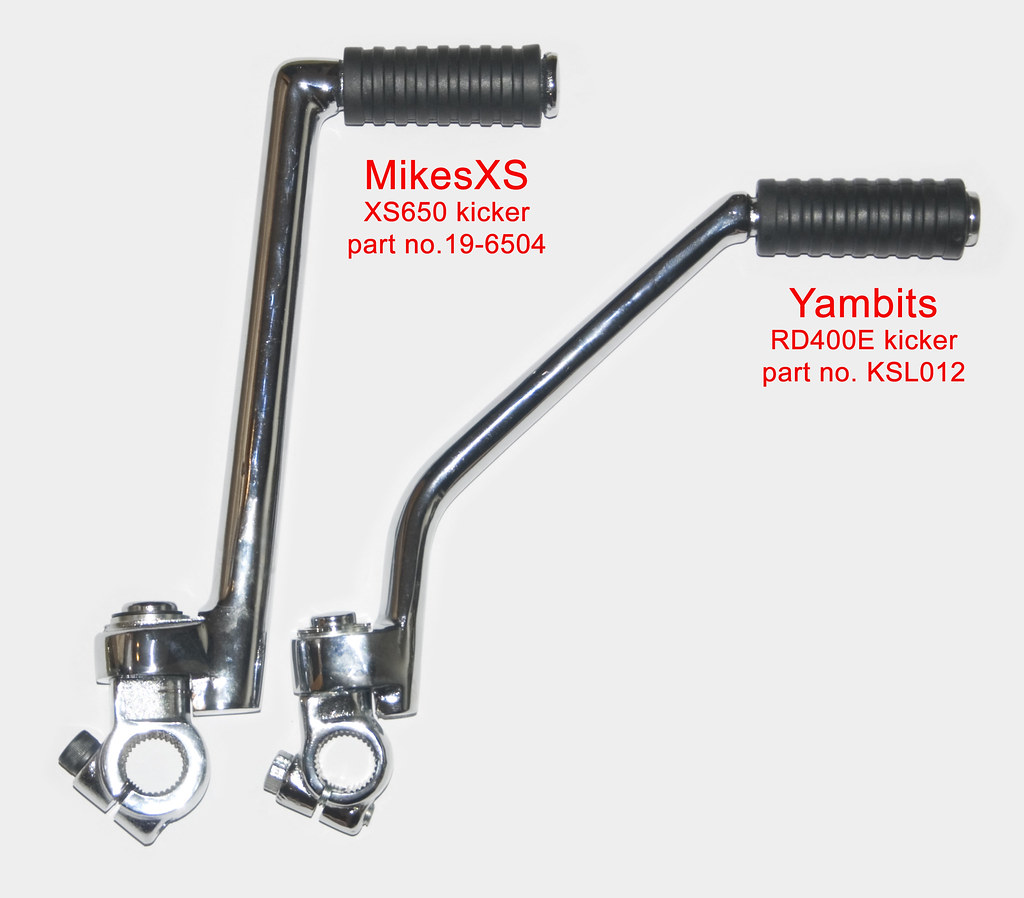

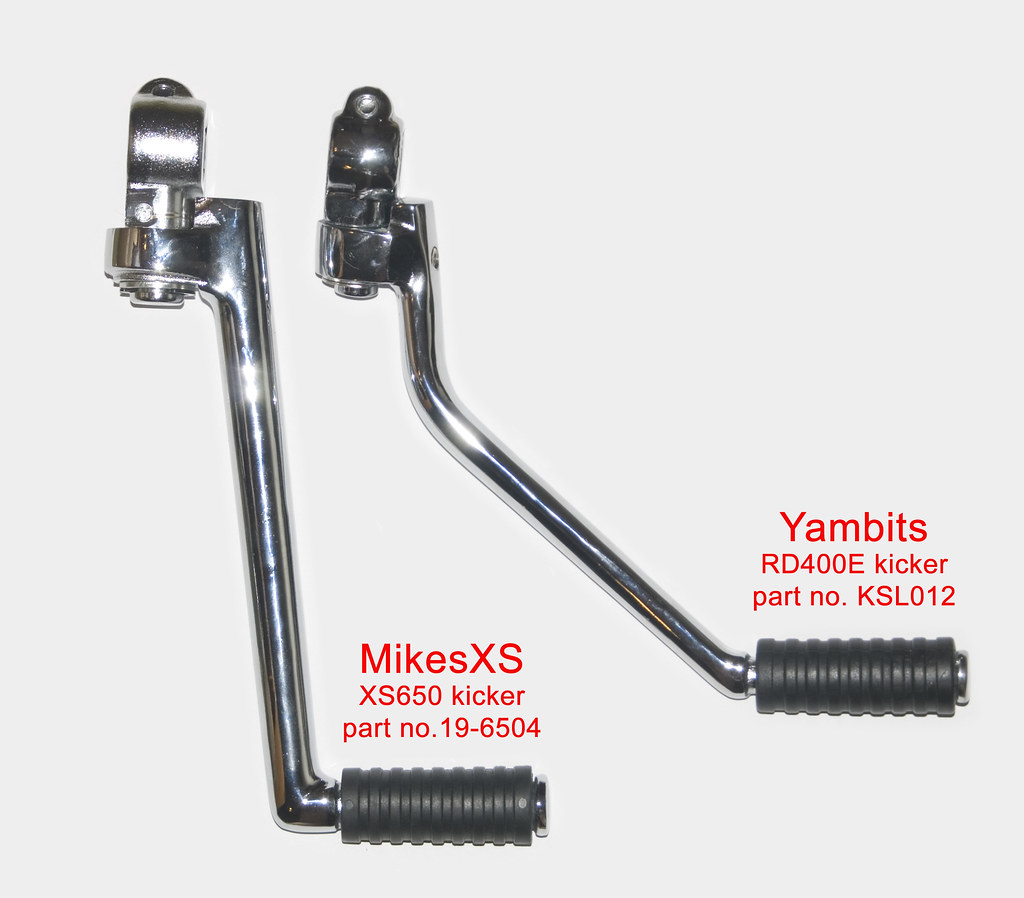

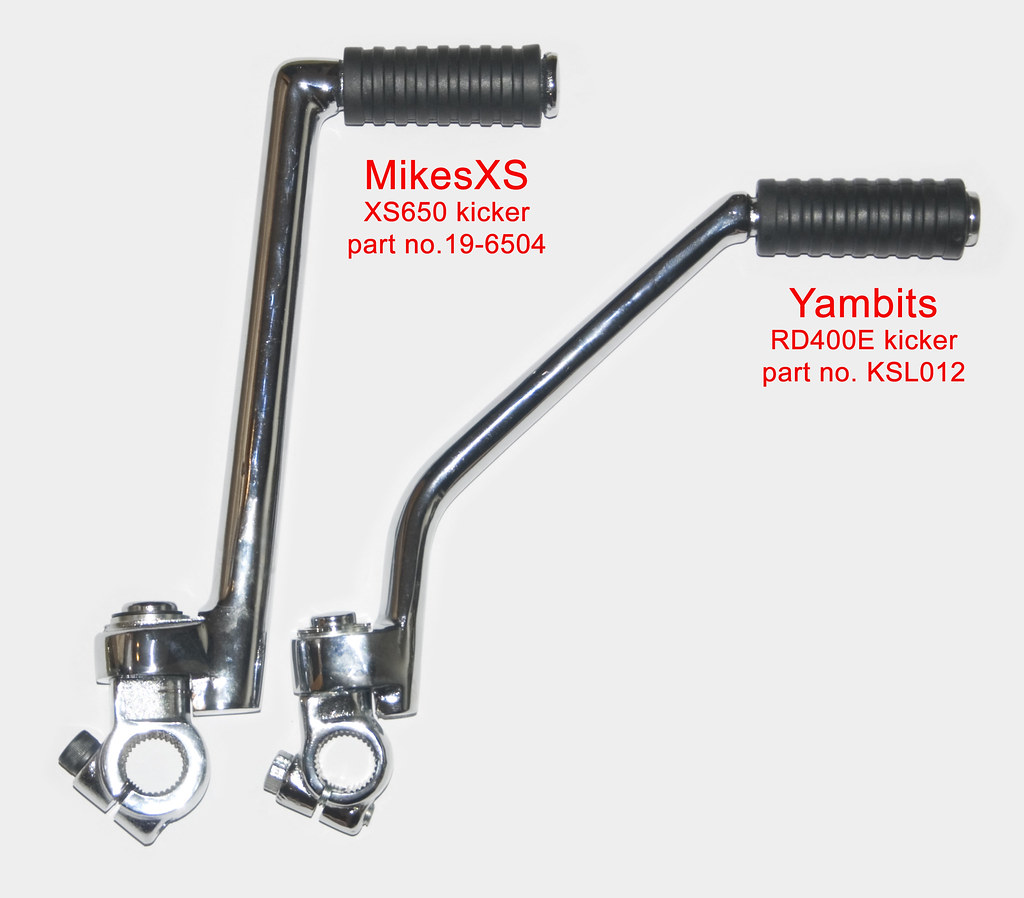

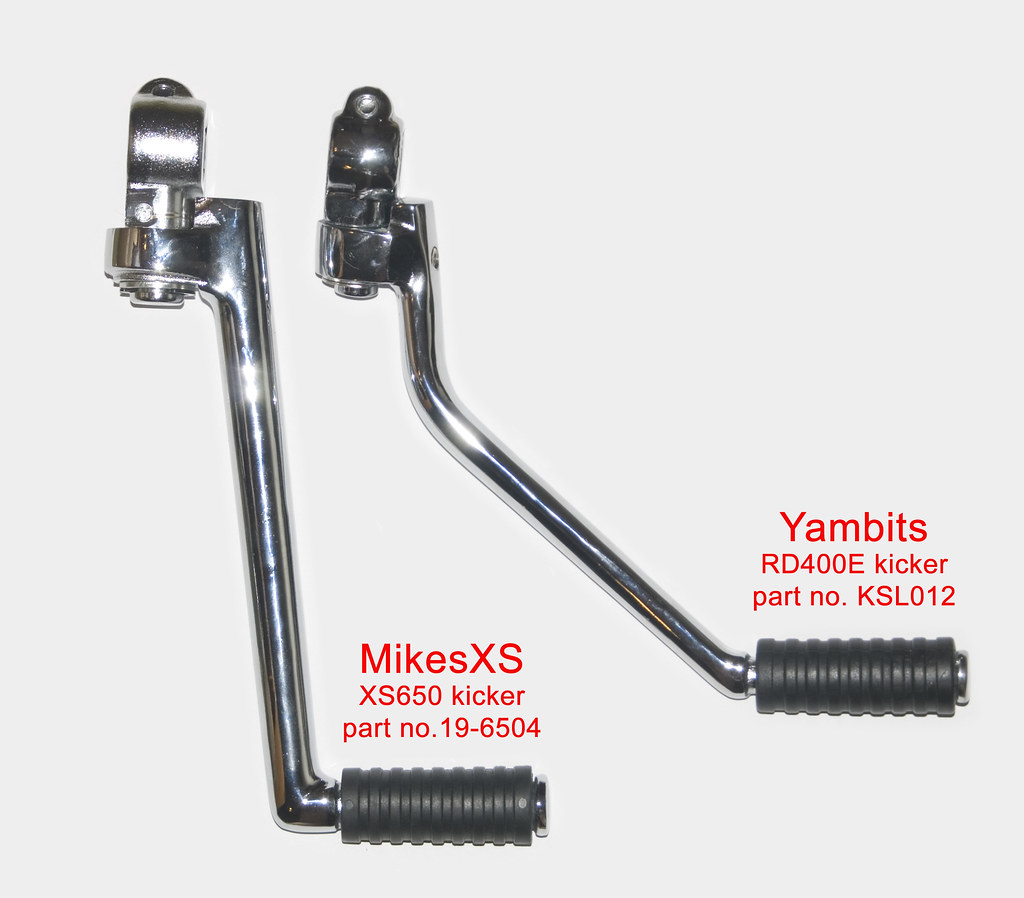

A concern that I had whilst most of the bike was together during the New Year period, was the fact that my beautiful brand new Mikes XS kicker smacked the Dunstall exhaust at the bottom of the stroke. For obvious reasons a solution needed to be found.

With my powers of research at full strength I managed to discover that the RD400E kicker had the same splined shaft mount. The most appealing aspect is that it has two bends that ensure the pedal pushes outwards during a downward kick. It should also blend in better than the straight XS650 kicker whilst in the "at rest" position. It seems to be of lighter construction yet am hopeful that it will be strong enough anyhow.

I picked RD400E kicker from Yambits.

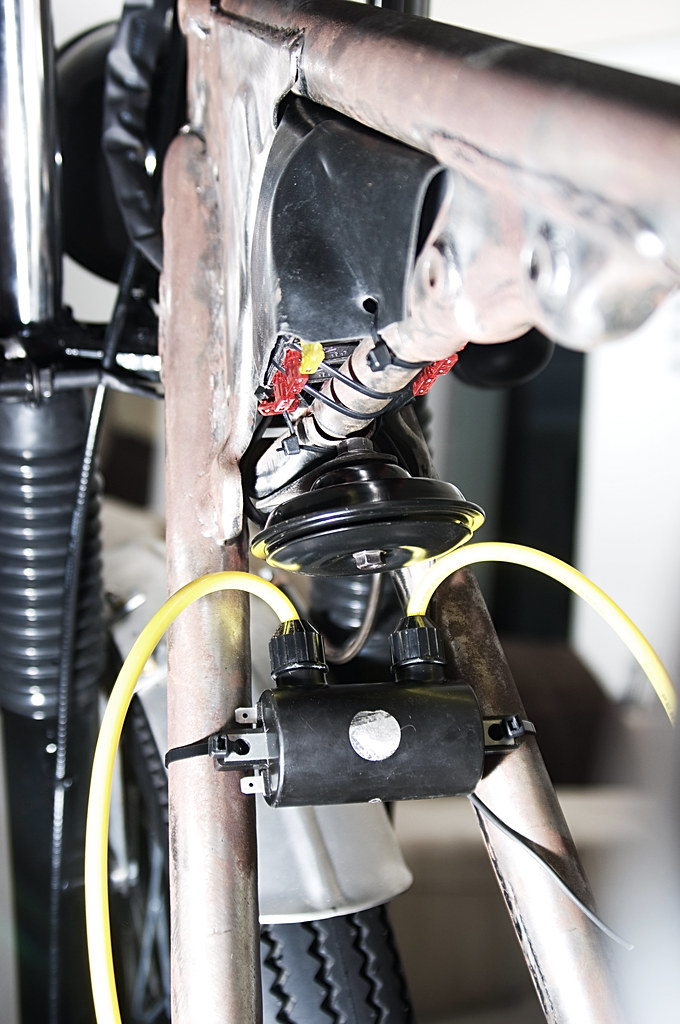

Below are some comparison shots I'd taken this evening.

DSC_1015

DSC_1016

DSC_1017

Cheers

Steve

Well it's been sometime since my latest update. Things are slowing down due to funds and electrical parts taking their time to arrive.

A concern that I had whilst most of the bike was together during the New Year period, was the fact that my beautiful brand new Mikes XS kicker smacked the Dunstall exhaust at the bottom of the stroke. For obvious reasons a solution needed to be found.

With my powers of research at full strength I managed to discover that the RD400E kicker had the same splined shaft mount. The most appealing aspect is that it has two bends that ensure the pedal pushes outwards during a downward kick. It should also blend in better than the straight XS650 kicker whilst in the "at rest" position. It seems to be of lighter construction yet am hopeful that it will be strong enough anyhow.

I picked RD400E kicker from Yambits.

Below are some comparison shots I'd taken this evening.

DSC_1015

DSC_1016

DSC_1017

Cheers

Steve

Comment