Haven't read thru this whole thread...so I'm not sure if anyone has addressed this yet, BUT...

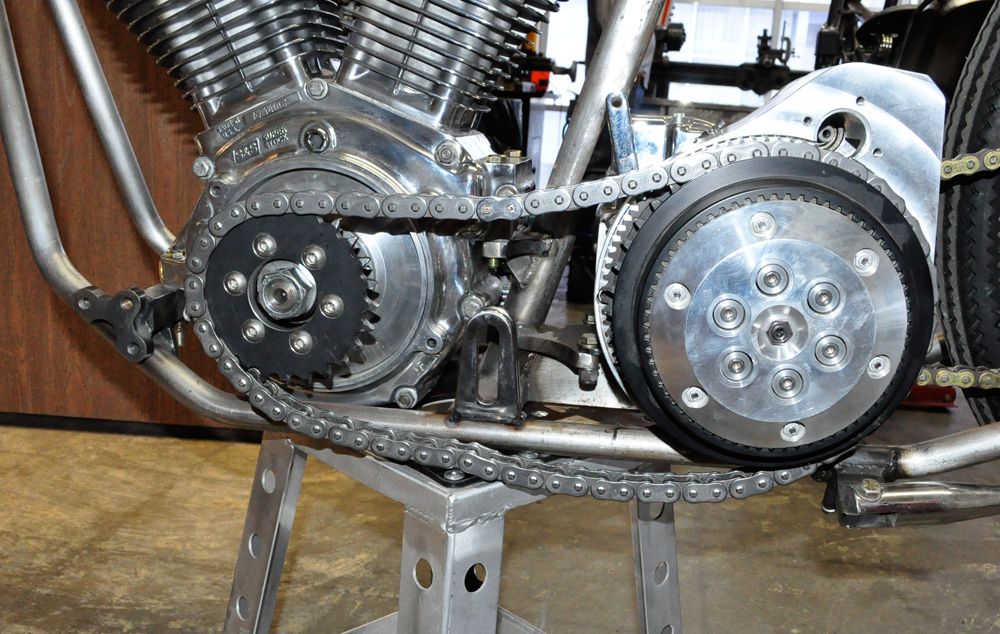

running a 5-speed trans with no motor plate (or inner primary, if you will) is NOT a good idea. Those thin little 5-speed tranny plates simply CANNOT withstand the vibrations and forces applied without the extra stiffness that a motor plate provides. Your trans plate WILL eventually fail.

And yes, I speak from experience...and we're not talking about some big ass motor either, in my case...stock 80" Evo. I built a bike around that same Tech Cycle setup. Had to eventually add an Exile motor plate (which required some machining on both the plate AND Isolator to work, but no biggie). Do yourself a favor and remedy the problem now...before it happens. And Tech Cycle should really stop manufacturing Isolators for 5-speeds.

running a 5-speed trans with no motor plate (or inner primary, if you will) is NOT a good idea. Those thin little 5-speed tranny plates simply CANNOT withstand the vibrations and forces applied without the extra stiffness that a motor plate provides. Your trans plate WILL eventually fail.

And yes, I speak from experience...and we're not talking about some big ass motor either, in my case...stock 80" Evo. I built a bike around that same Tech Cycle setup. Had to eventually add an Exile motor plate (which required some machining on both the plate AND Isolator to work, but no biggie). Do yourself a favor and remedy the problem now...before it happens. And Tech Cycle should really stop manufacturing Isolators for 5-speeds.

Comment