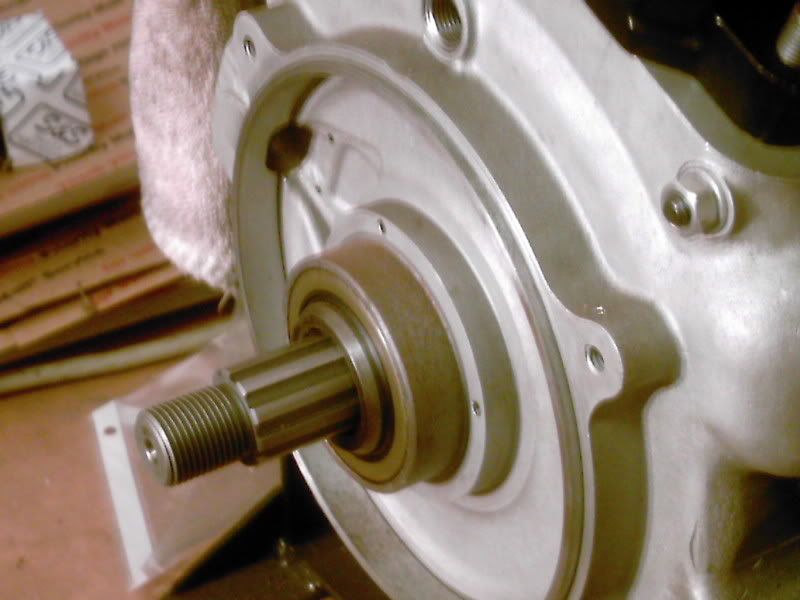

Anyone ever run across this problem? Pulled the inner primary on dad's old FXR to reseal everything. It's been leaking forever between the engine case and the inner primary. Well, this is why... the piece was still there, but it was cracked to the point of it falling off as soon as I touched it.

I think I am going to take it to work and see if we can mount it on the mill. If I'm careful, it might even be able to be done without tearing the motor down very far. I want to mill a circle around where the lip should be and cut it about 1/4" deep or so. Then hopefully make a new one from aluminum and press it in place.

If that don't work...

I think I am going to take it to work and see if we can mount it on the mill. If I'm careful, it might even be able to be done without tearing the motor down very far. I want to mill a circle around where the lip should be and cut it about 1/4" deep or so. Then hopefully make a new one from aluminum and press it in place.

If that don't work...

...

...

Comment